Bottling Tables

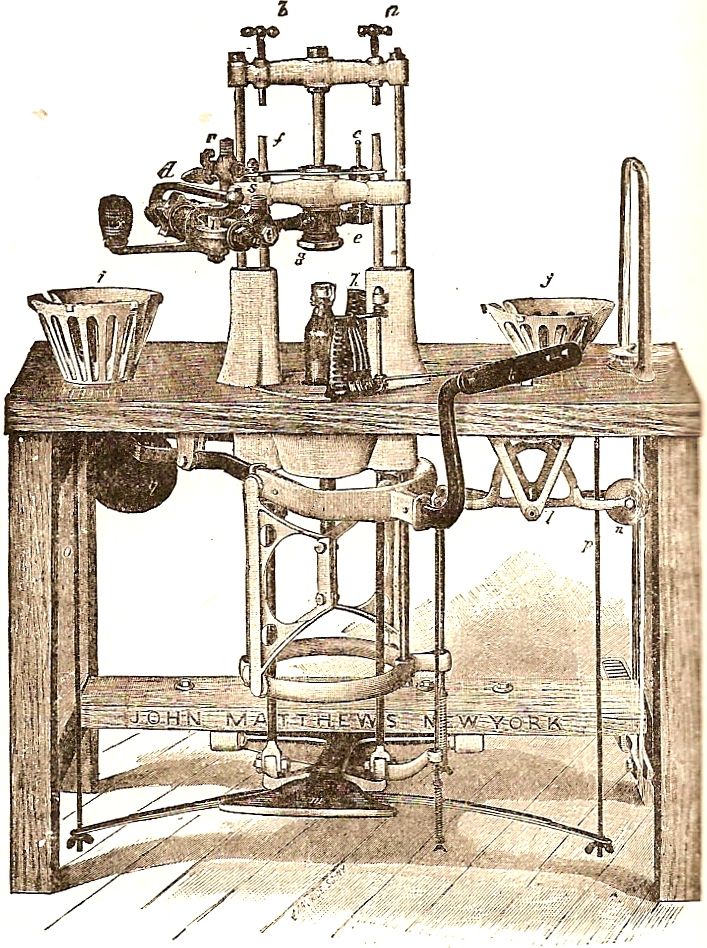

By the late 1880s, the knee bottling process had been replaced by far more efficient and economical bottle filling tables. In his 1888 book A Treatise on Beverages or The Complete Practical Bottler, Charles Sulz noted “The filling-machines may be placed at any convenient distance from the apparatus, the length of pipe only has then to be increased. This connecting-pipe is better throughout of pure block-tin. On American apparatus a flexible rubber hose is attached to connect with the apparatus, which should be of the best kind, compact, and stand the required bottling-pressures; it can be preserved and protected by laying it in melted paraffin of 100° C. (212° F.).” Sulz included an illustration of a bottling table supplied by The Firm of John Matthews in New York. The table was set up for bottling with corks and had a Matthews plunger syrup gauge attached. The parts were labeled as indicated:

The

description is as follows: a

and b, gauge screws to cork

gauge f, and

d, cork gauge.

This attachment enables all the corks to be driven uniformly and

to the proper depth into the mouth of the bottle.

When the cork is well in, the bottling-cylinder may be raised

sufficiently to allow the cork to be readily secured with the

cork-fastener.

c is an air valve or escape

valve for the atmospheric air in the bottle;

e, cylinder rods;

g, bottling-cylinder with

rubber packing inside; h,

automatic screen; i, quart

pot; j, pint pot;

k, hand lever;

l, walking-beam of the

automatic screen; m, foot

lever; n, balance weight of

the automatic screen; o, and

p, suspension rods of spring;

r, syrup-cock of syrup gauge;

u, cap of water valve of

syrup gauge; x, lever of

syrup gauge; y, balance

weight of hand lever.

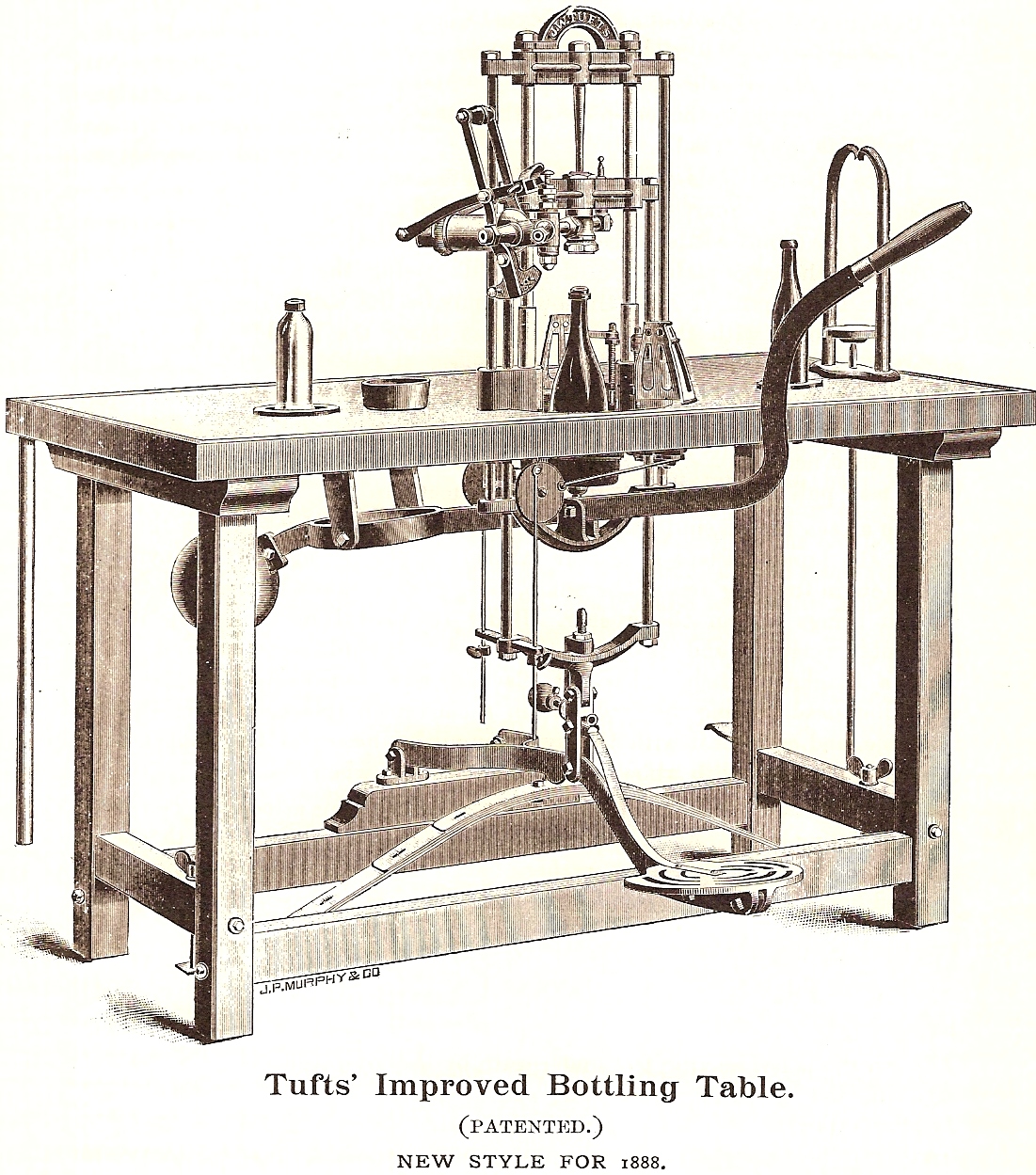

James W. Tufts’ 1888 book

The Manufacture and

Bottling of Carbonated Beverages illustrated a bottling

table that Tufts offered for sale, plus highly-detailed directions for

its set up and operation.

Accompanying the following illustrated are selected portions of

Tufts’ descriptions:

To Set up the

Table.

Place a bottle, of the size for which it is desired to

adjust the shield, in the proper position, – a quart bottle should be

placed in the bottom of the recessed plate pot; for a pint bottle place

the small plate in position; for a half-pint bottle place the large

plate in position, – and placing the foot on the treadle bring the

filling-head or cylinder down firmly on the bottle.

Close the shield around the bottle with the hand, and press down

the hand-lever slightly to enable the springs to catch and hold it in

place…

To attach the patent syrup-pump: Turn back the

check-nut on the long arm of the pump.

Place a leather washer in the filling-head or cylinder, and screw

in the long arm of the pump, using great care not to cross the thread

until it brings up on the washer.

Bring the barrel of the pump into a horizontal position, and turn

up the check-nut hard,

metal against metal with a monkey-wrench.

Do not place a washer between the check-nut and filling-head.

Hang the syrup can in a convenient place, or place it upon the

table, and connect it with the syrup-pump by means of the rubber tube.

A cock is provided with which to shut off the syrup when desired.

If the syrup-gauge is used, instead of the syrup-pump,

attach it by screwing into the filling-head.

As it has no check-nut, it will be necessary to use, on the arm

or in the filling-head, a washer of such thickness that the gauge when

screwed home will stand in the desired position.

The syrup-can must be placed in an elevated position if the

syrup-gauge is used.

Attach the rubber tube from the cylinders or fountains

to the water connection of the pump or gauge.

To Operate the Table.

Place a bottle in position for filling.

Place the foot upon the treadle and bring the filling-head down

firmly upon the bottle, at the same time bringing the cork-gauging pin

into position by placing the toe on the brass strap.

Place a cork, previously well soaked in warm water, evenly in the

top of the filling-head, and with the hand-lever drive it part way

through, using care not to drive it far enough to obstruct the passage

through which the syrup and water are to pass.

Having previously pegged the syrup-pump or gauge, and opened the

cocks which admit the syrup and water, make a backward stroke and draw

the syrup into the pump or gauge.

Then make the necessary forward stroke, throwing the syrup into

the bottle and opening the water-valve.

The air in the bottle should escape through the air-valve on the

further side of the filling-head, which may be adjusted by means of its

cup.

As soon as the bottle is sufficiently filled, make a

backward stroke with the pump, thereby shutting off the water and

drawing syrup for the next bottle, and drive the cork by a downward

stroke of the hand-lever.

Release the cork-gauge by raising the toe slightly from the brass strap,

still holding the filling-head down firmly on the bottle with the foot,

and raise the hand-lever a trifle to allow the pin to drop back out of

the way. Now let up on the

treadle, (still holding the handle-lever down firmly to retain the cork

in the bottle) which will permit the filling-head to rise from the

bottle sufficiently to allow the wire-fastener to be turned up over the

cork, or the bottle and cork to be seized with the corking-tongs if

desired to wire it. The

hand-lever may now be released, and when it has risen to its highest

point it will disengage the springs which hold the safety-shield, and

the shield will fly open.

The bottle can now be removed, and if to be wired, is taken to the tyer

where it is held while the wire is attached and fastened.

Keep the working parts of the table well oiled and

free from rust. Connections

are provided on the pot of the recessed-plate, on the air-valve, and on

one corner of the table, to which drain-pipes can be attached, for the

purpose of removing waste-water and keeping the table and operator dry.

The table should be so placed that the waste-water will run

toward the corner which is provided with the drain connection.

The cork-gauging attachment is a new improvement –

patent applied for – which takes the place of the wheel on the

cork-plunger, and which enables the operator to drive every cork exactly

the same distance into the bottles, no matter how they may vary in

height. But little practice

is required to enable the bottler to work rapidly with it, and it will

be found a great improvement and convenience.

The pin can be adjusted, by loosening the check-nut and screwing

the pin either up or down as desired.

As Tufts’ set up and operating descriptions indicate,

early bottling tables weren’t much more than corking benches.

A valve regulated the flow of carbonated water, a foot treadle

brought the filling head down onto the bottles, and a hand lever used a

pin to drive corks into the mouth of bottles after filling.

Higher end models included an automatic snifting valve and a

small safety screen encasing the bottle for protection in the event of

an explosion.

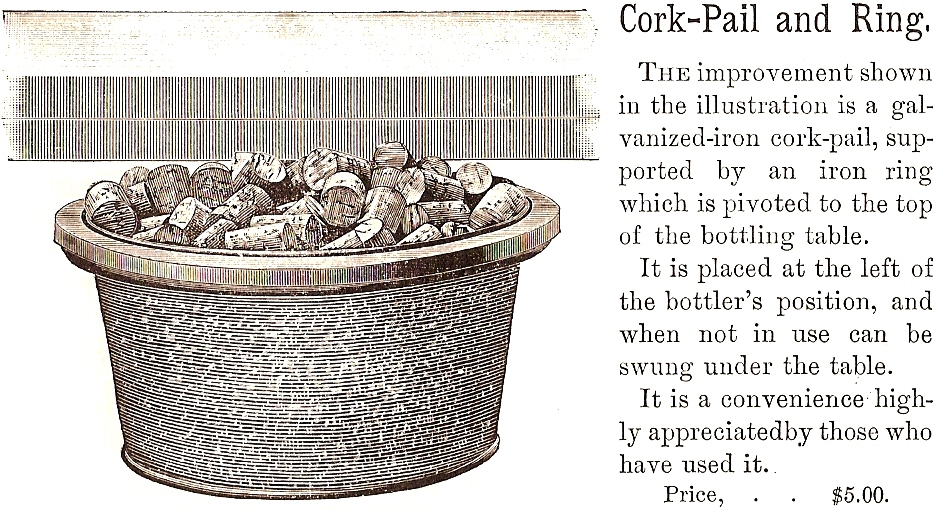

One of the options Tufts offered was this cork-pail:

HutchBook.com

HutchBook.com