Bottle Washing and Rinsing

In

addition to emphasizing the importance of pure water for bottling in his

1888 publication, The

Manufacture and Bottling of Carbonated Beverages, James W.

Tufts also advised: “Pure water should be used for washing bottles, as

well as for manufacturing the beverages, for it is useless to provide

pure water for the beverage if there are impurities left in the bottle

by the water used in washing.”

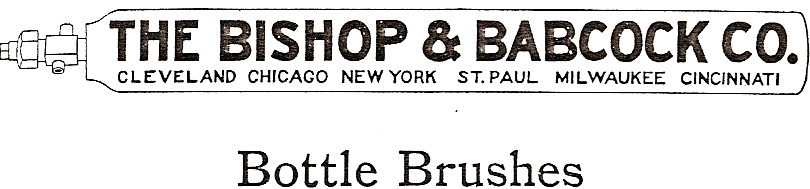

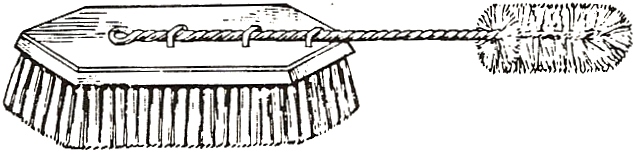

BOTTLE BRUSHES

Bottle brushes were used to wash

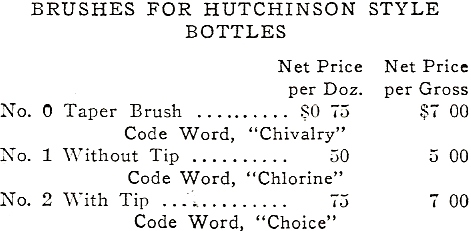

The W. H. Hutchinson and Son

1908

Bottler’s Book

advertised scrub brushes to be used for washing the outsides of bottles.

A layer of cork sandwiched into the two piece wooden handle

caused the brush to float:

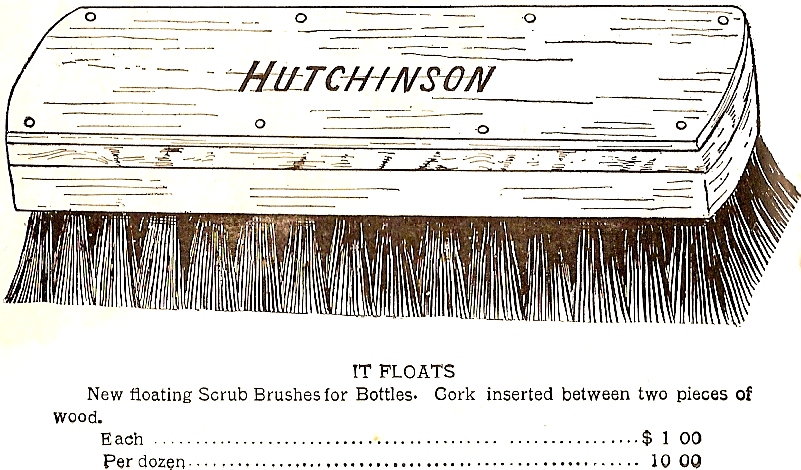

BOTTLE WASHING MACHINERY

Bottle

washing machinery was first introduced in the 1870s.

Most of the early power washers employed a rotating brush for

cleaning the insides of bottles.

Here is an example of a direct belt power washer available per

the 1908 Bottler’s Book

produced by W. H. Hutchinson & Son:

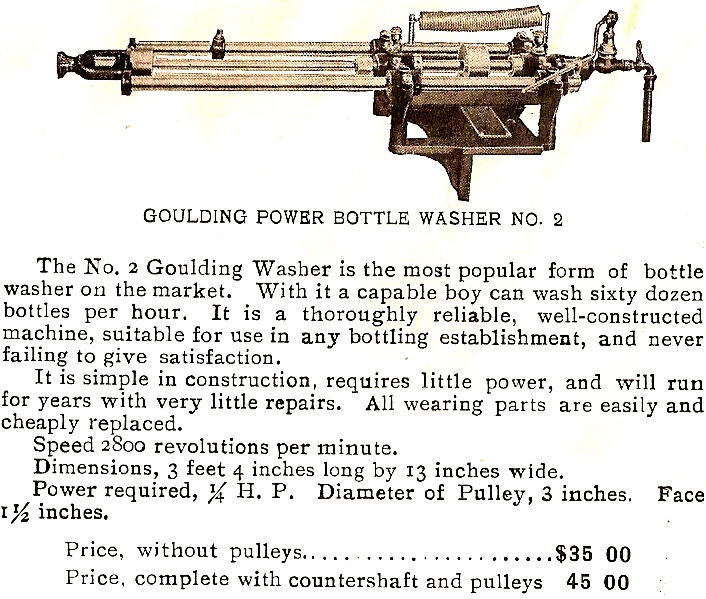

The 1908

W. H. Hutchinson & Son Bottler's Book also offered this more

sophisticated Goulding power bottle washer model:

Whew; the “capable boy” washing a dozen bottles per minute was definitely earning his no doubt meager salary!

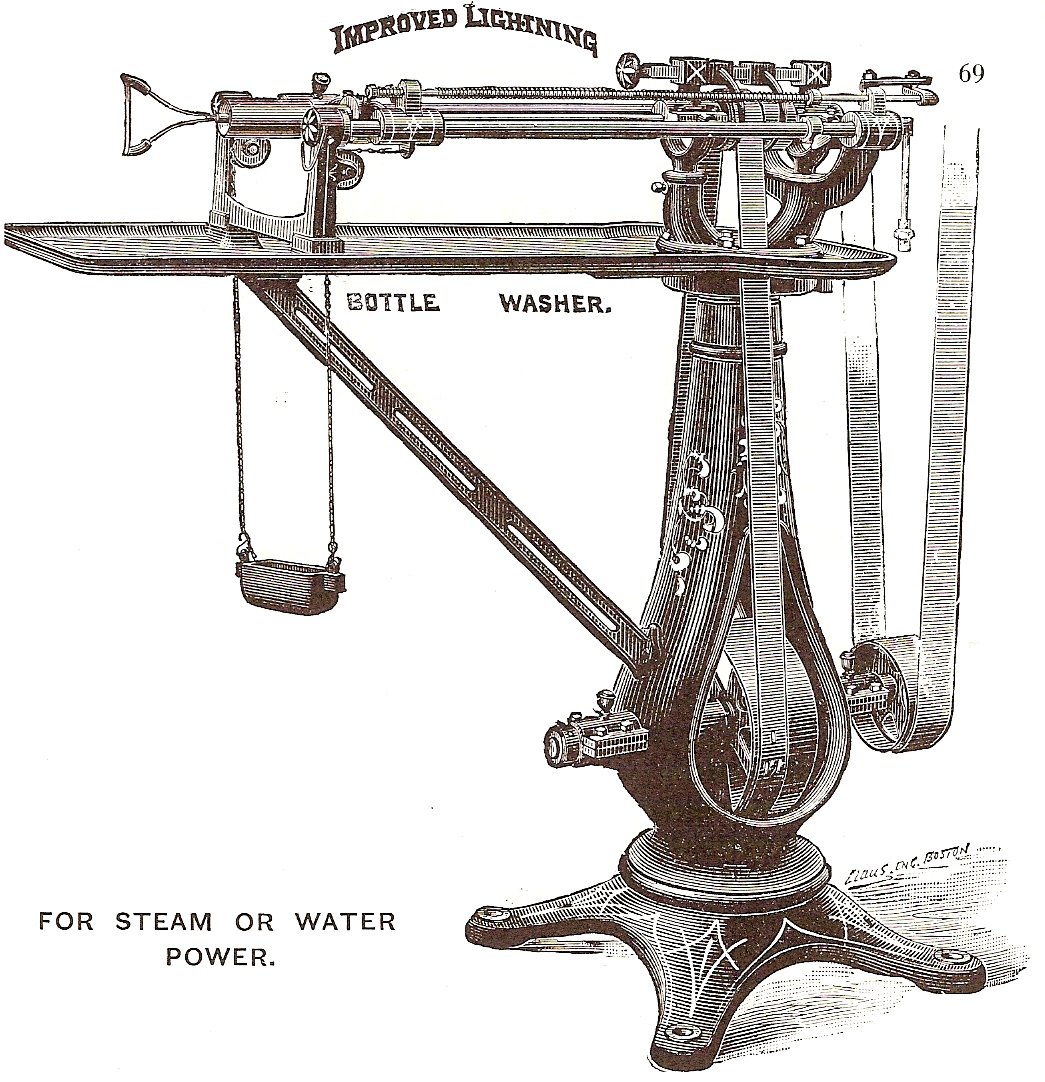

Larger-sized bottlers required bottle washing

machinery that could be used to clean a substantial quantity of bottles

in a short time period.

Here’s an example of the “Improved Lightning Bottle Washer” offered by

Tufts in 1888:

The

advertising copy accompanying Tufts’ advertisement specified:

I have sold to Messrs. Hoyt Bros. & Co., of

With this patent, together with those previously

controlled by Hoyt Bros. & Co., the Lightning Bottle-Washer becomes the

most perfect washer ever produced, and it is now difficult to see where

it can be improved. It is

perfect.

As these patents control essential principles which

all perfect bottle-washers must employ, it is at once apparent that all

washers that are at all serviceable must of necessity be infringements,

and so not safe to buy; while those, if any, that are not infringements

are unsafe to use…Price, $190.00.

Although Tufts claimed this bottle washer was

“perfect,” using it to wash

Some bottlers experimented with washers that shot a

pressurized stream of water into bottles, but the

SHOTTING MACHINES

The most reliable bottle washing equipment bottlers

depended on for cleaning

The following illustrations are from the 1910

W. H. Hutchinson and Son

Bottlers’ Supplies catalog.

Iron shot was 8¢ per pound, steel shot was 10¢ per pound, and

anti-rust cut steel shot was 12.5¢ per pound in 100 pound bags.

W. H. Hutchinson & Son promoted anti-rust steel shot because iron

and steel shot “have been objectionable because they become rusty when

used in water and leave rust stains in the bottles:”

Late in the

Bottle-Washing with Leaden Shot or

Emery.

Leaden shot are very extensively employed for

cleansing bottles…but unfortunately lead is smeary and extremely

poisonous. When bottles are

washed daily with shot a film of black lead will sometimes be formed…In

soda and beer bottles this film cannot be seen, on account of the

colored glass; but occasionally a shot can be seen that has become

wedged in at the bottom of the bottle, and held there, and thus

contaminating the liquid by the chemical action of the beverage on the

lead…shot for washing bottles is not to be recommended; and in our

opinion the cleansing of glass bottles with shot should be absolutely

prohibited where the bottles are intended for beverages.

Iron shot is preferable to lead shot, as it does not

affect the contents of the bottle.

This shot has sharp edges, cleaning the bottle more thoroughly

than lead shot.

Emery…is a very economical and practical substitute

for cleansing bottles, instead of leaden shot.

It occurs native in masses and grains, and is extensively used in

the arts for grinding and polishing metals, hard stones, and glass, and

can be used alone as well as with diluted acids.

It works much more rapidly than shot, on account of its sharp

angles, and is in every way an economical substitute.

Grains No. 5 or 6 are the most suitable for bottle-washing.

These

TO CLEAN STEEL SHOT.

By J. P. Sell,

Steel shot that has rusted together, and in which

a quantity of small particles of glass have accumulated, may be

thoroughly cleansed by placing the same in a pan of hot water.

By Joe Evans, Star Bottling Works,

When shot gets dull looking and leaves bottles

cloudy after shotting, take one-have ounce Citric Acid solution (the

same as you are using in your goods) to 1 pound shot, shake well in

a bottle and they will brighten up like new silver.

TO SAVE SHOT.

By E. W. Barnard,

There is a good deal of shot wasted by the

washers, and I find the best plan to collect the lost shot is to

pick it up with a magnet, which is much quicker than any other

method I have struck. I

use an old magnet, which came out of an old telephone battery, and

which I took from the waste heap.

RINSING MACHINES

Rather than rinsing bottles

by hand, many bottlers utilized bottle-rinsers.

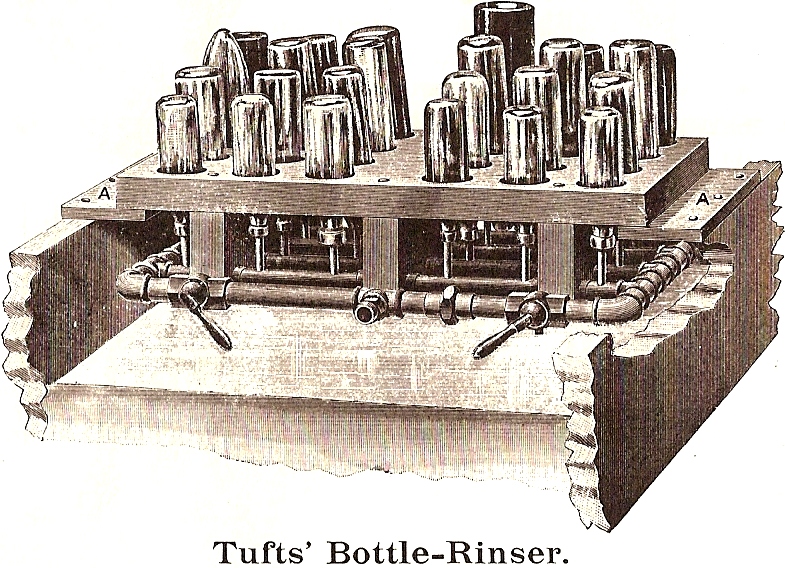

Here’s an example of a bottle rinser from James W. Tufts’ 1888

The Manufacture and Bottling of Carbonated Beverages

(look closely and note that in addition to

Hutchinsons, the illustration also features round bottom, torpedo, and

quart bottles!):

Tufts’

accompanying description indicated:

This simple and substantial bottle-rinser is intended

to be placed across a sink of any width greater than itself.

This is done by attaching to the sink the supports, marked ‘A’ in

cut, of necessary width.

The rinser is constructed of hard-wood and galvanized-iron tubing, and

is provided with two inlet-cocks, each side being entirely separate from

the other, so that water may, at the same time, be turned on at one side

and off at the other. It is

also provided with coupling to attach supply-pipe.

The rinser is arranged to take any size of bottle, and

hold it upright, as shown in cut.

When water is turned on at one side a powerful jet is

thrown inside each of the dozen bottles placed on it; and meanwhile the

dozen on the other size may be removed and replaced with others…Price,

$20.00

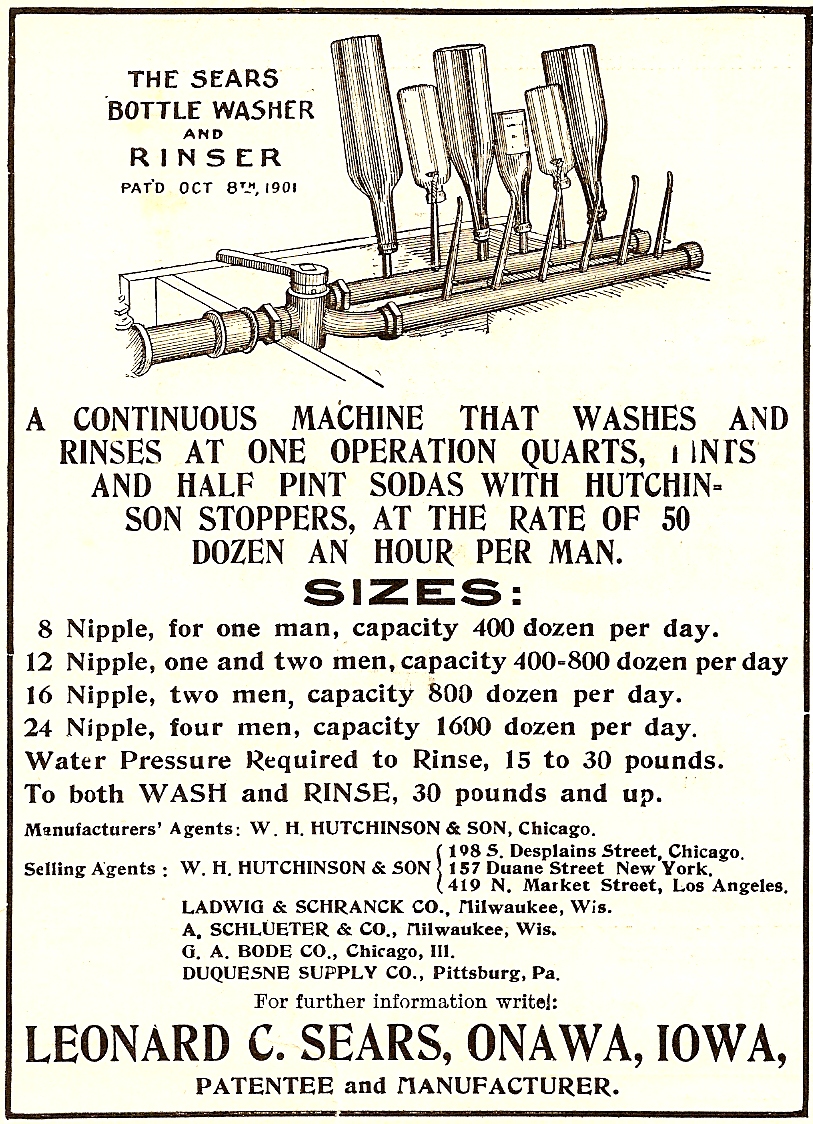

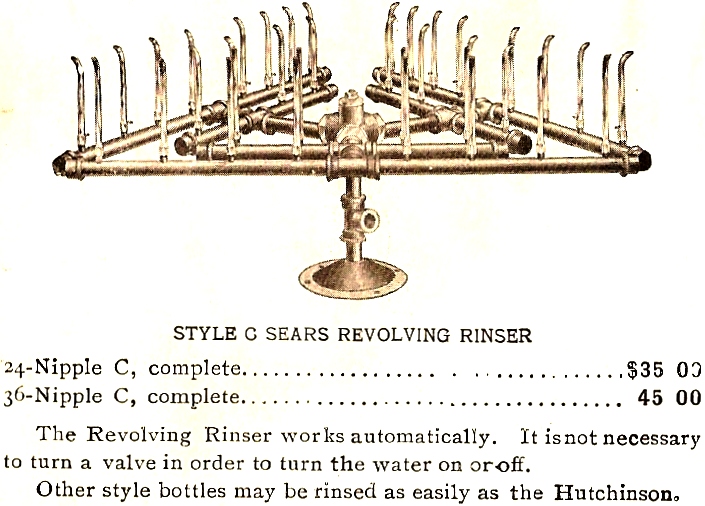

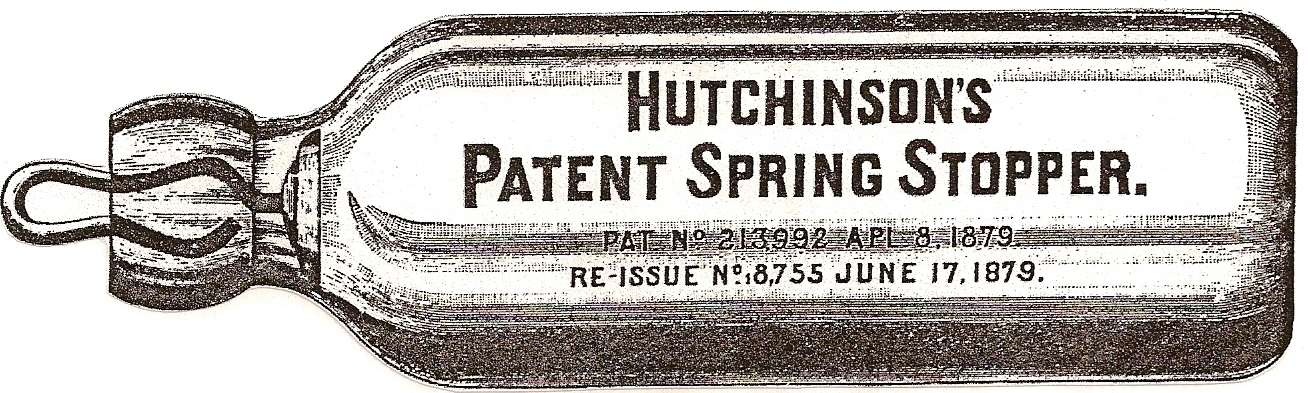

The following advertisement for The Sears Bottle Washer and Rinser (patented October 8, 1901) was placed in the October 5, 1903 National Bottlers' Gazette. Both of the pictured Hutchinson bottles have Hutchinson's Patent Spring Stoppers in place in their necks:

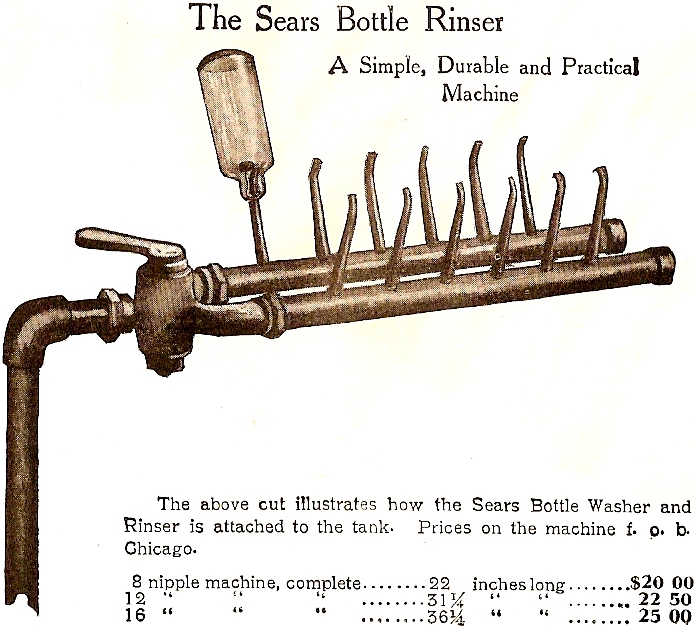

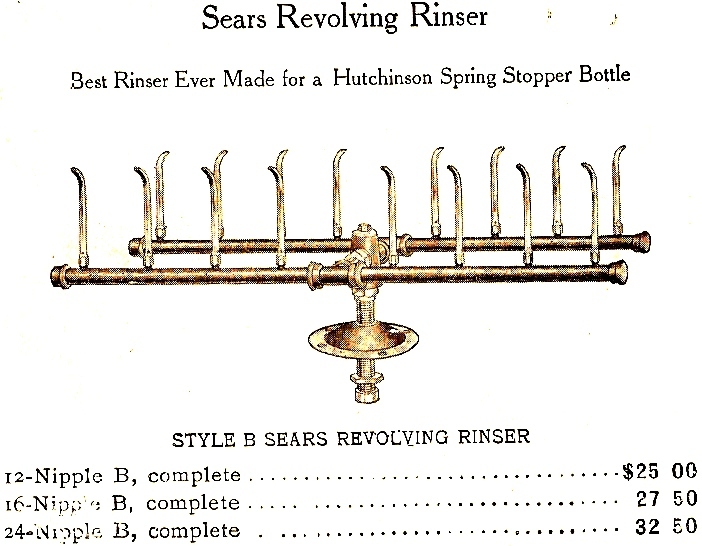

Here are examples of three bottle rinsing machines

offered in W. H. Hutchinson & Son’s 1908

Bottler’s Book.

The

BOTTLER HINTS

These

TO CLEAN NECKS ON

By W. F. Stein, Stein’s Bottling

Works, Clarion,

Use ordinary clothes pins.

This you will find better than a neck brush, as you do not

have any bristles to contend with.

I have used this for ten years.

INSTRUCT YOUR CUSTOMERS.

By R. K. Chadwick, Seale Bottling

Works,

It is a good idea to have your customers pull up

the stoppers of

COMBINATION BRUSH.

By T. L. Jordan, Flat Top Bottling

Works, Welch,

Get just a common scrub brush and one of the small

brushes used in cleaning necks, fasten the small brush on back of

the larger one. Double

pointed tacks are good things to fasten with.

You can readily see that you can wash out the side of bottle

and the neck without having to put down one brush to pick up

another, consequently saving time in that way.

BOTTLING GLOVES.

By Jeff. D.

When washing bottles in a rush, wear cloth gloves

of some kind rubbing the water on the outside while handling same.

This will clean the outside of the bottle quite as well as

the brush and is a great saving of time.

The gloves will also protect the hands from being cut by

broken bottles which might be in the tub, as well as from the

numerous little scratches one gets.

Gloves made from a common brand of canton flannel usually

give best service.

STERILIZED BOTTLES.

By Frank P. Dalzell,

We make a connection from the boiler direct to the

bottle rinser. The

bottles are first rinsed and then the steam is turned on, thus

saving a second handling.

Of course some of the bottles break, especially in cold

weather when the water is quite cold, but the percentage of breaks

is very small compared with the time saved in handling the bottles.

HutchBook.com

HutchBook.com