Safety

Many

bottlers were injured by exploding

Charles Sulz addressed the topic of safety in his 1888

book, A Treatise on

Beverages or The Complete Practical Bottler, with the

following comments and illustrations:

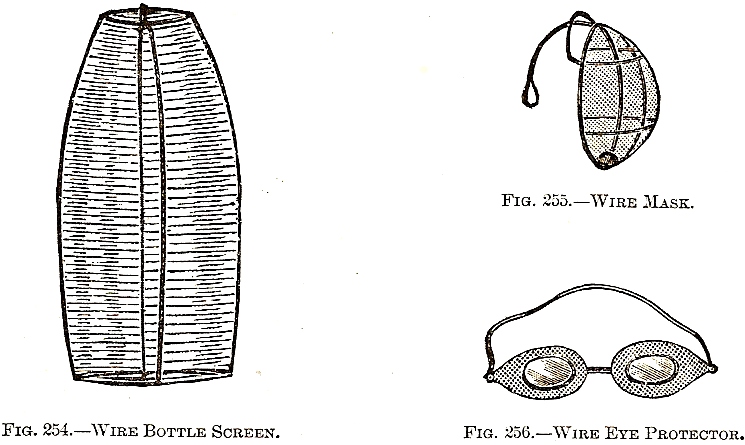

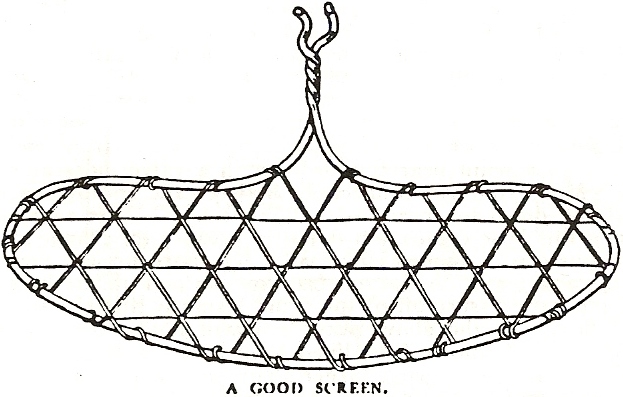

For the safety of the operator, to protect him against

injury from the glass fragments of bursting bottles, safety screens are

attached to the bottling machines as seen in the illustrations.

Instead of them, or even besides, wire bottle-screens are used,

especially where beverages under high pressure in pint or quart bottles

are to be filled, and their employment affords greater safety or

protection. These bottle

screens are made of steel wire, well tinned, and are strong and durable.

Other appliances for protection and safety for face and eye are

wire masks and wire eye protectors; for hands ‘bottling gloves’ are

used. When a moderate and

standard pressure is maintained for ordinary bottling the safety screens

attached to the bottling machines afford all the protection that is

necessary; for bottling highly charged beverages in large-sized bottles,

it is well to care for additional protection by employing the other

appliances.

Bottling

Pressure. – The usual pressure to bottle at should not exceed 60 to 80

lbs. for saccharine beverages.

Plain soda waters are frequently bottled at from 80 to 100 lbs.,

siphons at from 120 to 140 lbs. of pressure.

Carbonated beverages going to hot climates should not be charged

higher than 30 to 45 lbs.; but the liquid must be

thoroughly agitated to

impregnate it with gas.

No greater mistake is made by bottlers than when they attempt to

charge their beverages with excessive high pressure…

Complaints of bursting of bottles are frequent.

This is due to overcharged or badly annealed or cracked bottles,

and they burst nearly always in the process of bottling, as it is at

that moment that the greatest pressure is inflicted upon them.

The exploding of bottles afterwards is partly due to the same

cause, but also to changes in temperature and rough treatment while on

transportation and other similar causes.

Accidents not infrequently happen, and such of a most painful

character are known, and the carbonator can guard against them by

properly charging and bottling his beverages.

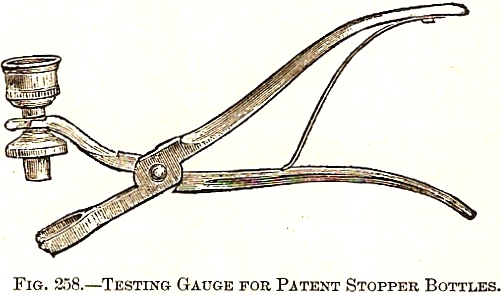

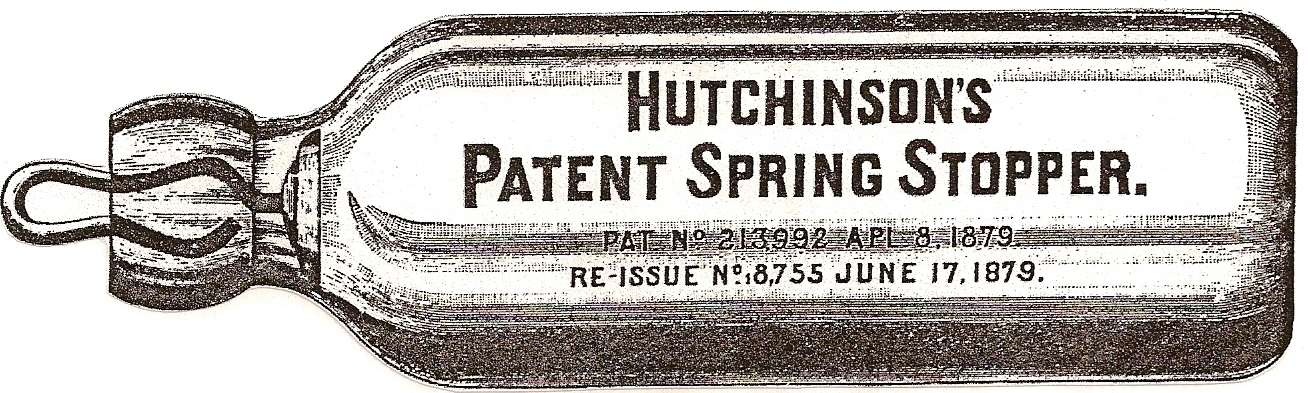

Testing Carbonated Beverages…A requisite for bottling

is a test gauge. This is an

instrument for ascertaining the pressure of gas in the bottles filled

with carbonated waters…Fig. 258 is a device for being attached to

the…pressure gauge and used when testing the pressure in

patent bottles.

The under part of the tongs is shaped like a fork: this is placed

under the ring or neck of the bottle, when, by compressing the handle,

the plug on upper part will be brought on to the top of the stopper in

the bottle, and so force it away from its seat the pressure can now be

noted, and by reversing the bottle the tongs can be taken off, the

stopper will take its seat, and the bottle be again closed.

Early

industry trade publications contained numerous references to mishaps

involving bottlers. Here’s

an example from the December 15, 1897 issue of

The Western Bottler:

S. F. Ellingwood demands that the Omaha Bottling

Company pay him $5,000 for an eye he lost while in the employ of the

defendant. Ellingwood

alleges that he was employed by the defendant, laboring as a soda water

bottle filler. While so

engaged, he alleges, on September 6th last, a bottle exploded

and that fragments of the glass flew into his eye, destroying the sight

of the organ. He further

alleges that the machinery in the factory was defective, as was the

bottle, and that consequently the defendant is responsible for the

accident.

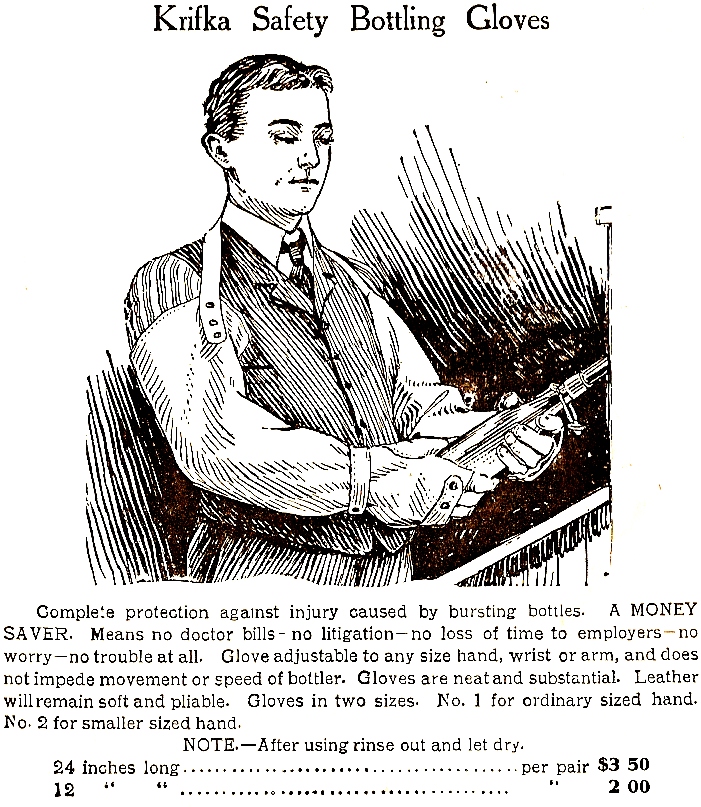

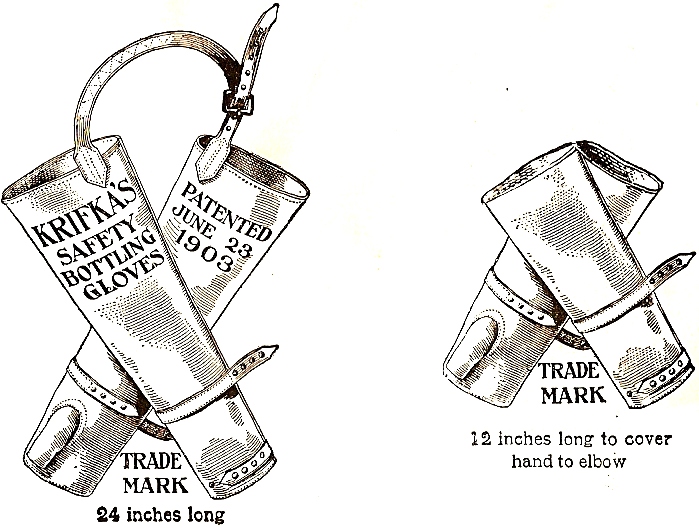

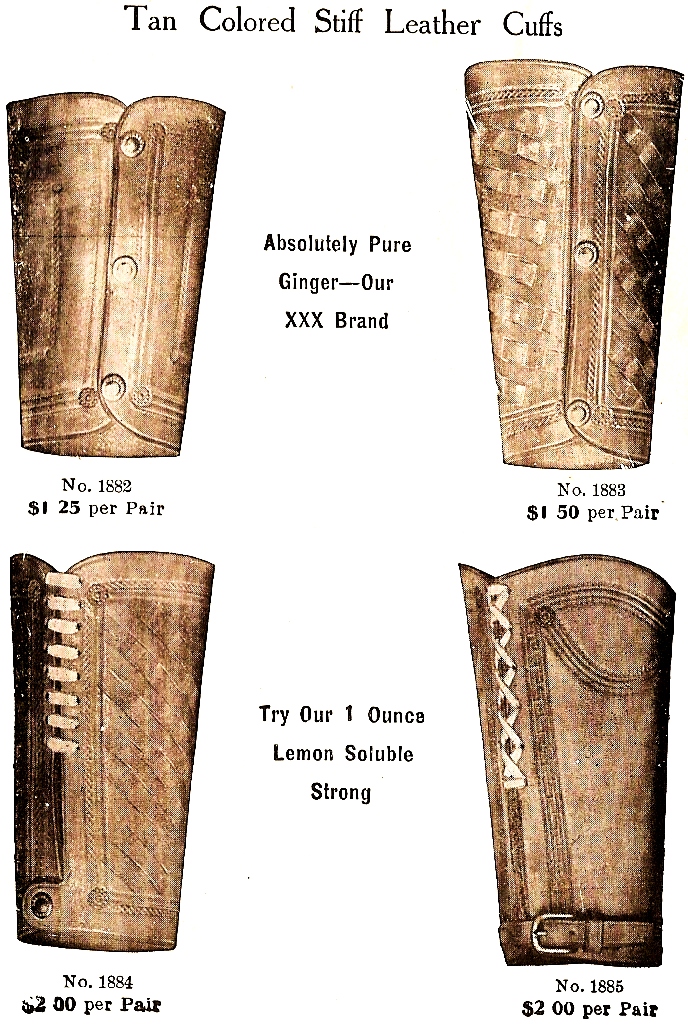

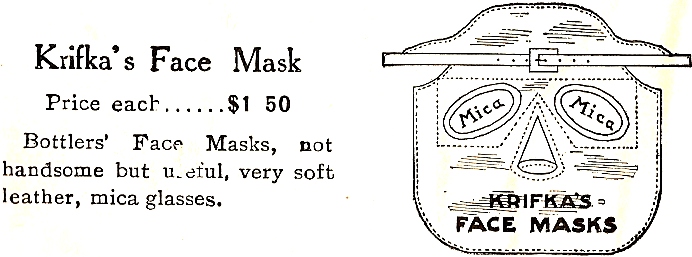

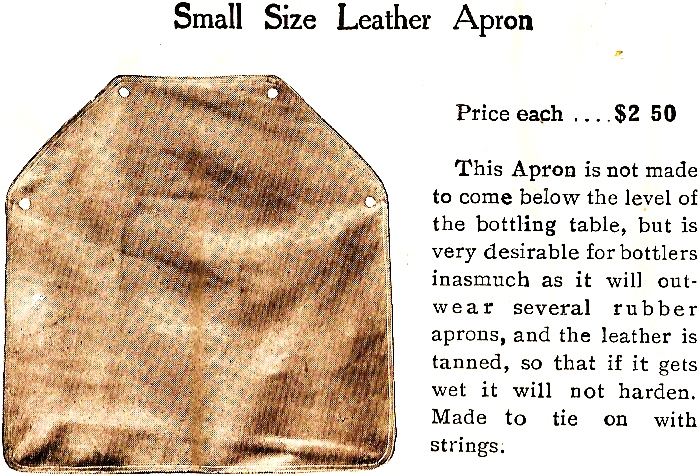

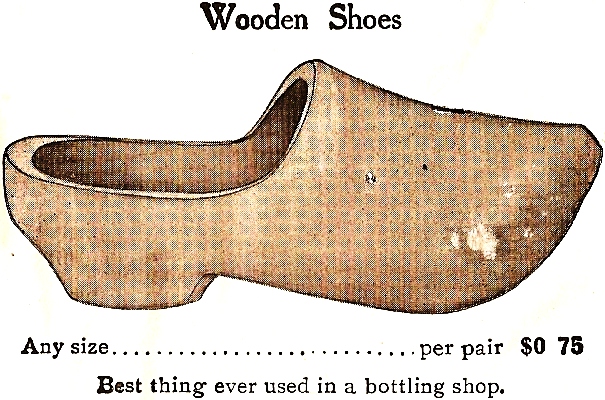

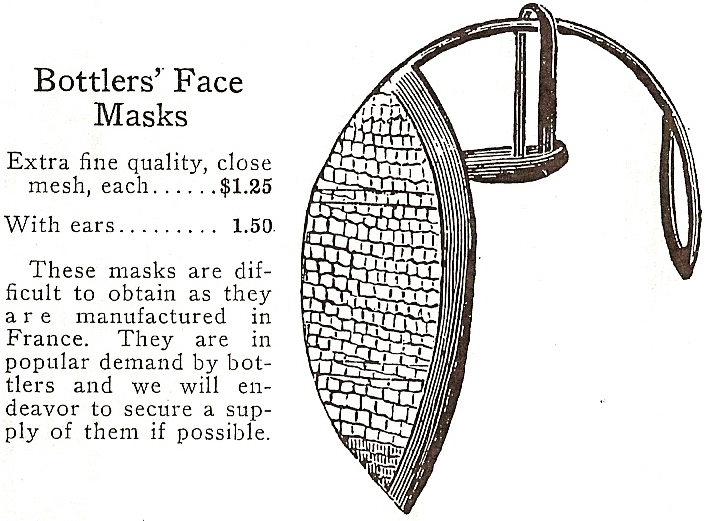

W. H. Hutchinson & Son supplied numerous safety-related products specifically designed to provide additional protection for bottlers. Here are examples of several items advertised in their 1908 Bottler's Book:

Most of the bottling industry

supply houses offered face masks during the

These

BODY PROTECTOR.

By Wm. Stier, Jr.,

A screen for

BOTTLING GLOVES.

By Mrs. M. Kaufman,

To prevent cuts in bottling take an ordinary pair

of woolen gloves and cover outside with five or six sheets or

cotton. A piece of

cloth or fine leather is then placed over this cotton.

This makes a good bottling glove, being far superior to the

rubber glove, which allows water to run up the arms.

This glove absorbs the water.

DRY FLOORS.

By Davison & Welch,

To keep from getting wet when bottling with the

HutchBook.com

HutchBook.com