Labeling Bottles

Like

several other aspects of the

Labeling Bottles.

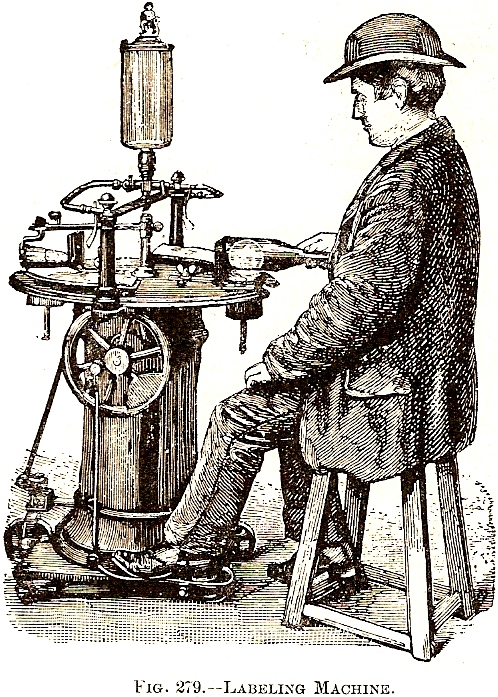

This is, like capping and foiling, an ornamental part

of the bottlers’ work, but it must be done tastefully, as an attractive

label also enhances the value of the beverages.

Ever for this kind of work mechanical devices are not wanting.

This machine is manufactured by

Barnett & Foster in

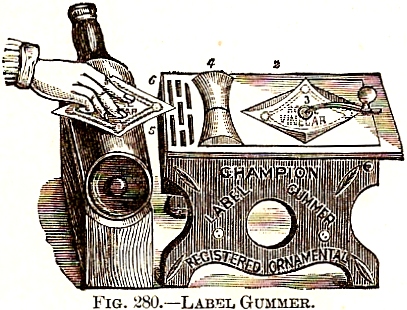

A Label Gummer

is offered by Geo. J. Hutchings,

Labeling machines became far more sophisticated toward

the end of the

Although

the accompanying advertising copy lacked detailed operating

instructions, one can easily surmise this machine was designed to

greatly standardize and speed the process of labeling bottles.

It weighed 100 pounds and sold for $100, f.o.b. from the factory.

These

TO SAVE TIME IN LABELLING.

By Concho Bottling Works,

Have a smooth piece of tin and spread paste thinly

over surface, take labels and fold in center, then fold back edges.

You can now take the labels and set them in the paste.

The one on bottom will adhere.

Raise the balance and repeat until each one has been placed

on the paste board. I

use from ten to twelve labels at once.

You can now pick up one label at a time and place it on the

bottle, and I find a small boy can label as fast by hand by using

this method as one man can bottle, and besides you only paste on the

extreme edges of the label, and it is much easier for them to soak

off.

DAMPEN YOUR LABELS.

By J. B. Mayer,

Bottlers who label by hand will find it greatly to

their advantage to dampen labels before placing same on bottles, for

taking a dry label and wetting it with paste and slapping it on the

bottle will invariably show wrinkles in label.

Paste label well, slap it against a second label, dividing

paste put on first between the two.

Lay the pair aside for some minutes or until you have pairs

enough for one case.

Then turn pile of labels over, using those first pasted, then they

will stick to bottles readily, show no wrinkles and do quicker work.

ANOTHER METHOD.

By Chas. C. Hogan,

Use a one-inch flat brush and have a small board,

say 6 inches by 10 inches.

Put about what paste the brush will pick up on one end of the

board. Spread it around

and lay the labels on the other end of the board.

Pick up a label and wipe both ends across the paste on the

board and it is ready to put on the bottle, which of course you will

have in your left hand.

PASTE.

By

By Sedro-Wooley Bottling Works,

G. L. Simmons,

Yuncker Bottling Works,

Geo. Mills, 407 Broadway,

J. S. Henninger & Son, Henninger

Bottling Works,

To make a good label paste, dissolve 2 ounces of

Gum Tragacanth in 1 gallon distilled water.

If too thick dilute with carbonated water.

A small lump of alum added to it will keep it from souring.

To make it more adhesive add a little brown sugar.

By Frank Belard,

Use a quart can in making the paste.

Two tablespoonfuls of flour, and add enough water so as to be

made like a cream. Break

up all the small lumps of flour, then fill the can with boiling hot

water and stir on the back of the stove until it is well mixed.

Do not use paste until it is cold.

If it gets too thick, add hot water.

By A. M. Britt,

To make a good paste for sticking on labels or

shipping tags on boxes and casks: Gum Arabic dissolved with sour

beer and heated by inserting a steam hose into it.

By Geo. Ritter,

If labels do not stick well on bottles, take one

tablespoonful of brown sugar to a pint of paste.

By

A good labeling paste that won’t smear your

bottles: Dissolve two heaping tablespoonfuls of good flour in

one-half pint water.

Dissolve a little lye and pour in enough to cook it, and then add

enough water to make about two quarts.

This makes a good cheap paste.

HutchBook.com

HutchBook.com