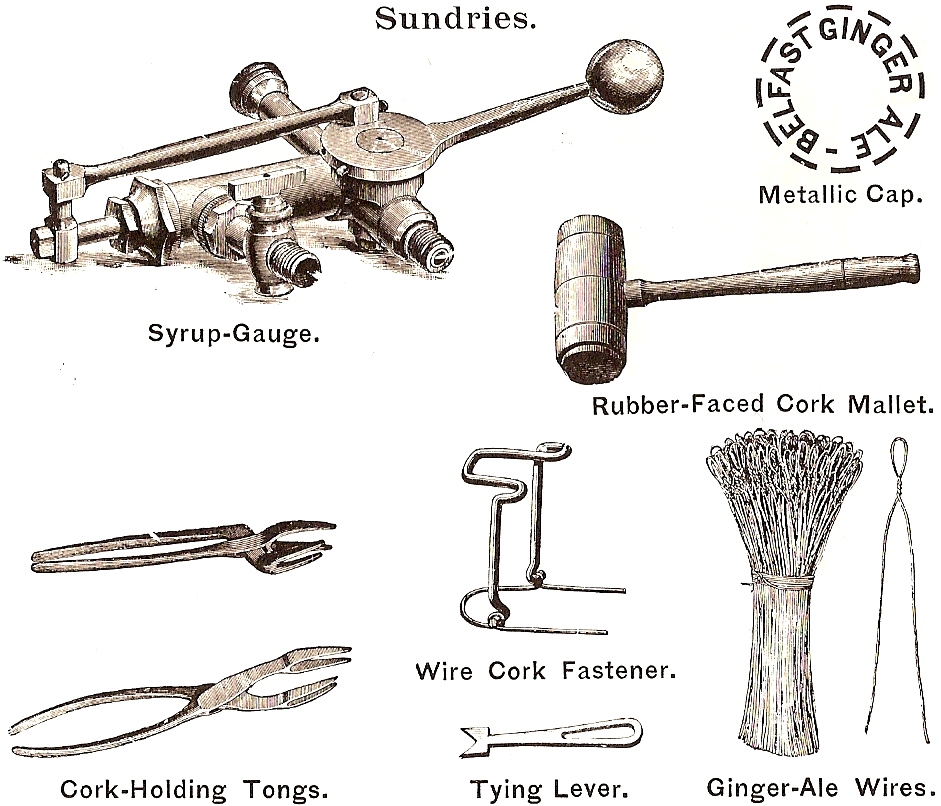

Syrup Gauges/Pumps

The introduction and on-going

development of syrup gauges/pumps substantially improved the bottling

process, allowing operators to rapidly dispense accurately measured

quantities of syrup into each bottle.

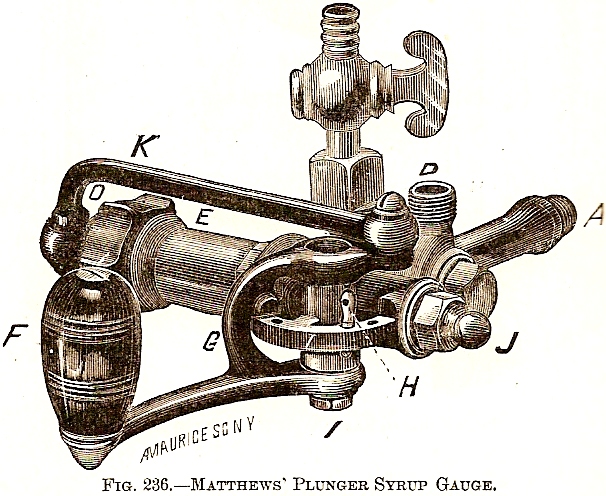

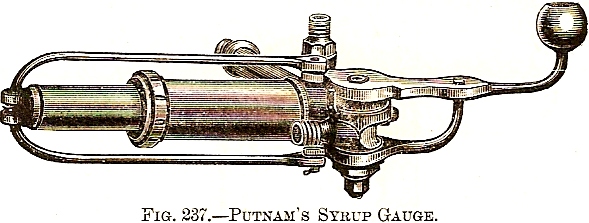

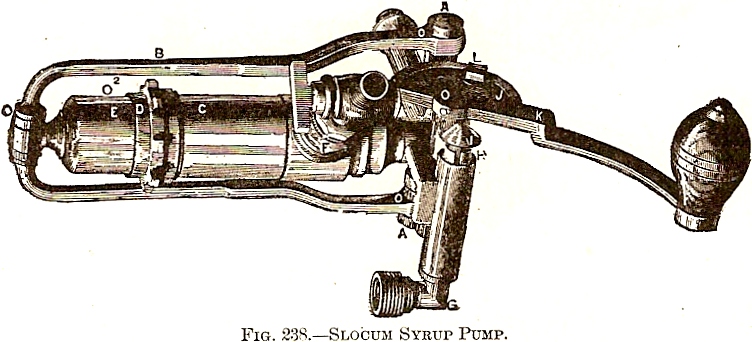

The following three drawings from Charles Sulz’s 1888 book

A Treatise on Beverages or

The Complete Practical Bottler show syrup gauges/pumps

produced by Matthews, Putnam, and Slocum.

The illustrated Putnam gauge is quite similar to the version

Henry W. Putnam patented October 29, 1861 (U.S. Patent No. 33,602).

Although Putnam’s gauge was expensive at $20, it was a welcomed

labor-saving device.

Sullz’s

general comments about these syrup gauges/pumps included:

Their capacity is from ¾ of an ounce to 4 ounces of

syrup per stroke, and the desired quantity is regulated by means of a

movable pin or screw which guides the pumping strokes…All these syrup

gauges or pumps are made with close-fitting hard rubber plungers, which

fill the entire cylinder – that is to say, they admit and discharge the

syrup from the same end of the piston.

It is necessary to have the syrup cans or tanks elevated in order

to deliver the syrup to the syrup gauges.

A gauge with suction pump will

draft the

syrup whether elevated or not.

The syrup gauges and pumps are made of brass and ought to be

carefully and frequently tin or silver lined inside, as the acidified

syrups which are compelled to pass through all parts of it would soon

affect the metallic body and get tainted with metallic impurities

itself, and consequently contaminate the beverages.

We have seen syrup

gauges entirely covered with verdigris on the inside, and

this is another point where the carbonator should exercise the closest

scrutiny and cleanliness.

The gauge must be frequently cleansed, and whenever the lining is worn

out at once re-lined.

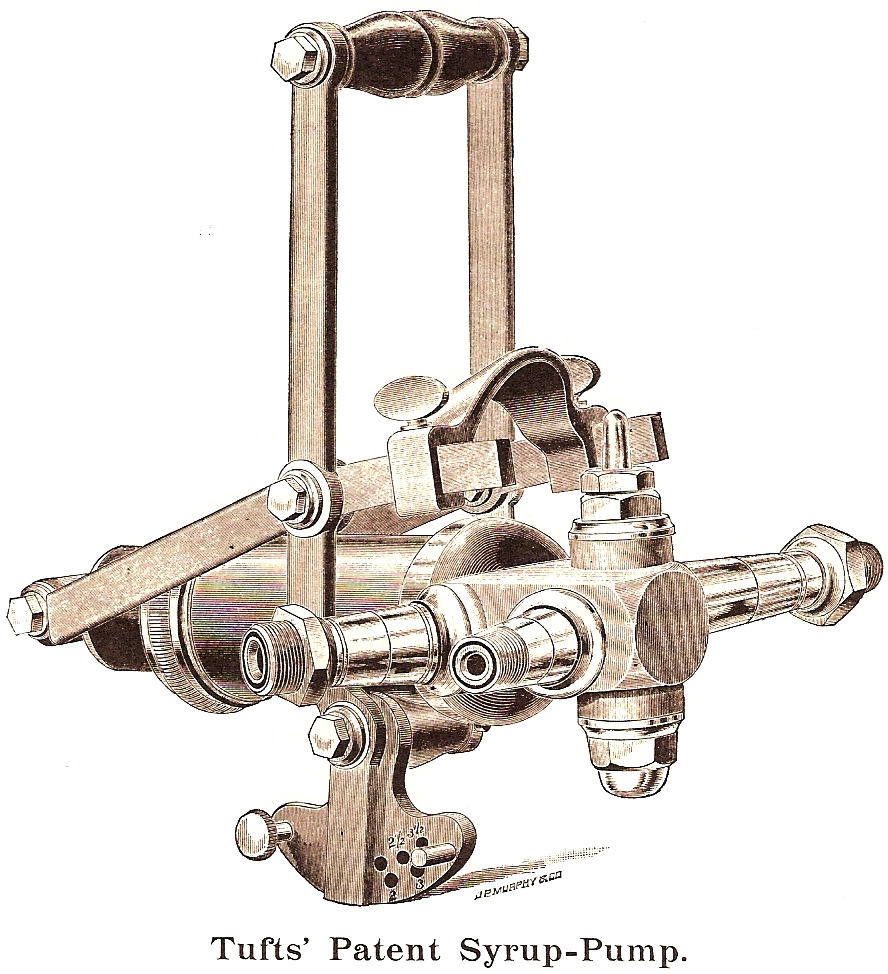

Here’s the syrup-pump offered by James W. Tufts in his 1888 book The Manufacture & Bottling of Carbonated Beverages:

Tufts’

description and directions mentioned:

This is the only pump made which is lined throughout,

including the barrel. The

solid plunger and the syrup-valves are of hard rubber; they require no

packing, and are not liable to get out of order.

The water-valve being on the outside is convenient to repack or

rewasher when necessary.

This is a section pump, and it is not necessary to have the syrup-can on

a shelf, on or hung to the ceiling, as it will draft from any place that

any suction pump will draft from.

The beverages which pass through this pump will be absolutely

free from contamination.

The bottler who is so particular to have his fountains lined with

block-tin to protect his soda and mineral-waters from metallic taint,

and who is compelled to pass these waters and his acid-syrups through a

syrup-pump or gauge lined with verdigris, will appreciate this pump.

Directions.

In adjusting this pump to the filling-head, place a

washer in the female of the filling-head, and screw the pump in until it

brings up firmly on the washer.

Turn the pump around until it is in a level position, convenient

for working, then screw up the loose nut on the outlet passage of pump

against the filling-head.

This nut is intended for a check-nut, and must be screwed up tight to

prevent the pump from turning when in use.

At the end of the upright arm is a disc with screw pin

and poles for gauging the quantity of syrup.

The outside holes are for 1 oz., 2 oz., and 3 oz., and the inside

holes for 1 ½ oz., 2 ½ oz., and 3 ½ oz.

For four oz., let the arm strike the stationary pin; placing the

movable pin for safe keeping in the hole which is not marked.

The operation of the pump is a forward and back direct

motion, making the stroke very short.

The opening of the soda-water vale is at the extreme end of the

stroke, and the syrup is all discharged from the barrel before the

water-valve is opened.

The pump may be adjusted as desired, to open the

water-valve wide for quart bottles or slightly for half-pint bottles, by

moving the slide on the arms and setting it by means of the

thumb-screws.

In the late 1860s The Firm of John Matthews marketed

the first counter-pressure snifting valve.

This valve directed gas expelled

from a bottle during filling directly back into the carbonated water

supply hose where it could be re-used.

This not only conserved gas, it created a uniform pressure in the

cylinder and bottle, reducing foaming in the bottles to a minimum.

Snifting was a highly important step in the bottling process.

Although developments such as syrup gauges and pumps

greatly improved the filling process, major bottle closure improvements

were slow in coming and bottlers continued to seal bottles with corks.

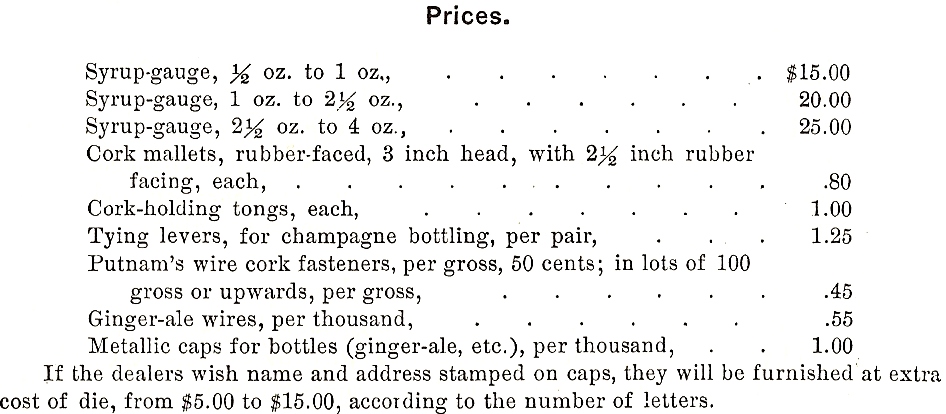

As late as 1888, Tufts was offering the following capping and

wiring supplies:

The

descriptions accompanying Tufts’ listings (plagiarized from Charles

Sulz’s 1888 A Treatise on

Beverages or The Complete Practical Bottler) detail how

bottlers utilized these tools and supplies:

Capping and Wiring.

The tyer will be found of assistance in capping and

wiring. It is shown

attached to the end of the bottling-table and consists of an iron arch

sufficiently high to allow the bottle to be placed under it, and of a

movable platform which can be raised by means of a pedal.

The bottle while under the cork-plunger of bottling–table is

seized with the cork-holding tongs and placed on the platform, and by

pressing on the pedal with

the foot, the bottle is brought up against the top of the arch, thus

holding in the cork while the tongs are removed and the wire applied.

The price complete, ready to attach is $7.00.

The best annealed broom wire should be used.

It should be cut in pieces of proper length and each piece folded

double, and twisted six or eight times to form a loop at the end.

The helper, on taking the filled bottle from the table with the

cork-holding tongs and placing it under the tyer, quickly seizes a wire

with his right hand, puts it around the neck of the bottle, giving it a

couple of twists to hold it firmly in place, and passes the ends through

the loop, draws tight, cuts off the superfluous wire with shears, and

presses the ends into the cork.

The pressure in the bottle has by this time forced the cork

against the wire, so as to make a neat looking job.

When the tin foil is used in capping, it is previously

cut in sheets of the proper size.

The operator places a sheet on the palm of his left hand, covers

it with paste, and taking the bottle in his right hand, he places the

neck on the sheet of tin foil, and by a dexterious turn wraps the latter

about the bottle neck and cork.

There are many accessories which can be advantageously

used in wiring and capping, if desired; such as the cork-holding tongs,

for taking bottle from bottling-bench; the tying-lever for tightening

wire over cork; the rubber-faced mallet for driving back a cork which is

escaping; the metallic cap, often used in place of tin foil.

HutchBook.com

HutchBook.com