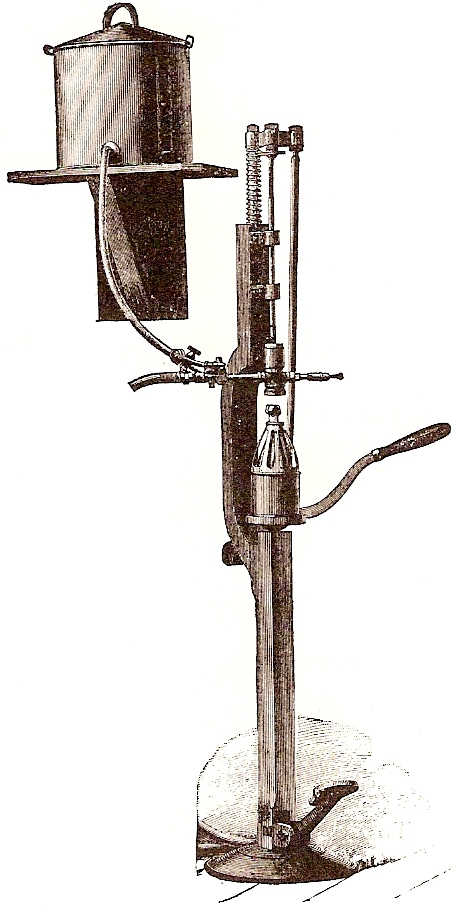

Upright Bottling Machines

Some smaller bottlers opted for less expensive, upright bottling machines that didn’t require as much space as conventional bottling tables. Such machines didn’t gain much popularity because they were more difficult to use than regular tables and slowed the entire bottling process. The illustrated machine is from The Manufacture & Bottling of Carbonated Beverages, an 1888 book published by James W. Tufts, a major bottling industry supplier.

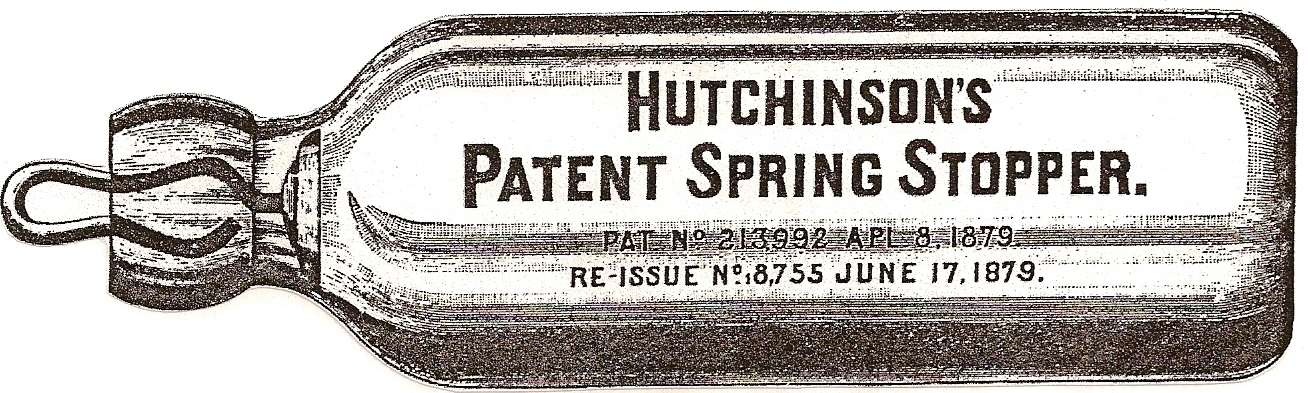

This is a new invention, especially designed to save cost and transportation charges of the wooden table…many dealers do not use the table, but prefer to use boxes placed alongside of the machine. It has several features which commend it to bottlers. The entire absence of the side rods and cumbersome parts of the old bottling-table allow it to be used with great rapidity, while the fixed bottle-shield is always in place without being in the way, and is adapted to any size bottle without change, by simply placing a block on the bottling plate. The bottle is raised by the foot lever and held against the rubber packing of the soda-cock while being charged. The plunger for corking is operated by the hand-lever and carried back by the spring. The frame is of iron, and although very strong and substantial, is cast hollow, and therefore light. Attached is a syrup-pump and syrup-can, making this one of the most complete machines in the market, while is price is lower than any. This machine is designed for use with Putnam fastener. An attachment for the use of the Miller, Klee or Hutchison stoppers, with the bottling machine or bottling-table, can be furnished at an extra charge of $10.00.

Directions for

Using.

First see that your corks are well soaked in hot

water, which will soften them so that you can force them into the head

of the bottle easily. Place

the bottle in position upon the stand, and by pressing with your foot

upon the treadle force it up into the filling-head, place the cork in

top of filling-head and taking hold of handle of the lever, force it

(the cork) down, but not so far as to obstruct the passage from the

syrup-gauge, then open the syrup-gauge for the passage of soda and syrup

into the bottle, and after it is full, force the cork into the neck.

To put the wire over the cork, ease up on the treadle, and at the

same time follow the cork with the ‘plunger’ until the treadle brings up

solid on the base, which will give you plenty of room to arrange the

wire. Be sure that the

air-valve in the side of the filling-head is not screwed up so tight as

to prevent opening, while you are filling, to let the air pass out.

While the machine is new, the use of a little lard on

the passage way of the cork would be judicious, until it gets worn

smooth by passing of the cork.

An adjustable block admits the use of different size bottles.

We have this year discarded the spring, and use

instead a weight on the end of corking-lever.

This improvement makes the operation of the machine much easier.

HutchBook.com

HutchBook.com