Water and Filtering Systems

Water

has always been one of the greatest keys to a bottler’s success.

Well water was considered ideal for bottling purposes as it often

contained carbon dioxide gas in its natural state.

Water from deep wells was often considerably lower in

temperature, an important attribute because the cooler the water, the

more easily it is saturated with carbon dioxide.

W. H. Hutchinson & Son recommended “if you can reduce it to a

temperature of 35 to 45 degrees, the charging will be more thorough.

By carbonating in this manner, charge is visibly increased when

the goods are subjected to a warmer temperature.”

Impure water could taint or react with soda water, giving it a

rancid taste. Almost all

bottlers who relied on city water supplies utilized a filtration system

prior to using city water for bottling.

James W. Tufts stressed the importance of pure water

in his 1888 publication,

The Manufacture and Bottling of Carbonated Beverages,

when he advised:

Success in the bottling business depends in a great

degree upon the water. The

water used should be PURE.

By this I mean it should be free from organic matter.

The sale of certain popular brands of so-called mineral waters

has attained enormous proportions.

Many of these waters are simply pure spring water highly charged

with carbonic acid gas.

Spring water is the best for carbonator’s use…The first care of the

bottler of carbonated drinks should be to secure a bountiful supply of

pure water. He is indeed

fortunate who possesses a spring or well, in the water of which chemical

test can find no decaying vegetable or animal matter.

All are not so fortunate, especially the city bottler, who must

often depend on aqueduct water, usually unfit for use without

filtration. A simple and

practical test for organic impurity is by adding a small quantity of

Permanganate of Potash, about one-fourth of a grain to the gallon of

water to be tested, and allowing it to stand for a time.

The permanganate will impart a faint purple tinge to the water,

which will gradually disappear if organic matter be present.

The more impure the water the sooner the purple color will

disappear, and if very impure a dirty straw color will take its place.

The water should

always be tested.

Its outward appearance, clearness, brightness and tastelessness,

is not proof of its purity.

If the water be impure, and better cannot be obtained, it must be

filtered before using.

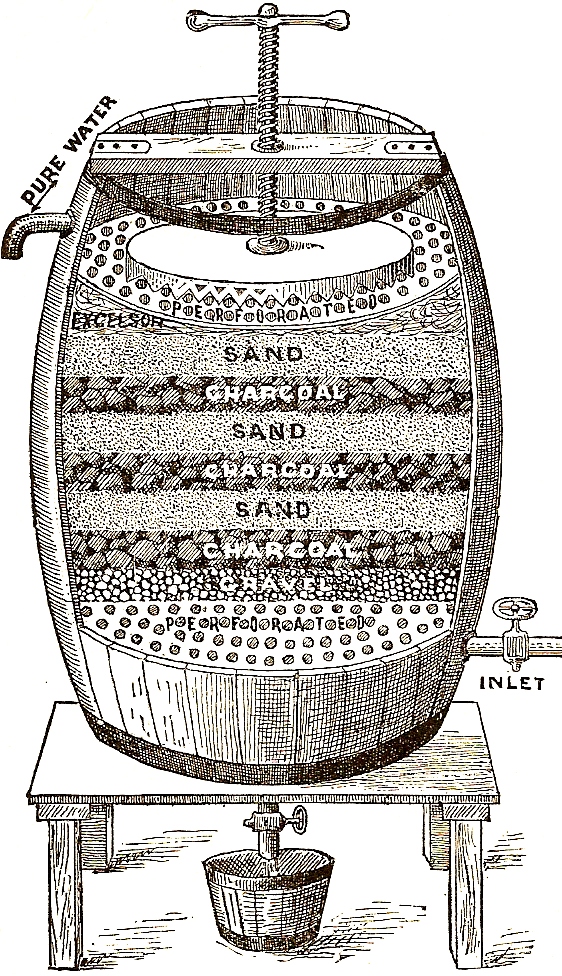

Although numerous types of commercial water filtering

systems were marketed to the industry, many bottlers constructed

homemade systems. The

homemade filtering system illustrated below first appeared in the

September 1883 National

Bottlers’ Gazette,

and was reprinted in James W. Tuft’s 1888 volume,

The Manufacture and

Bottling of Carbonated Beverages, and again in Charles H.

Sulz’s 1889 book, A

Treatise on Beverages or, The Complete Practical Bottler.

Sulz’s accompanying description

mentioned:

Arranged from a 50-gallon wine cask with a false

bottom, perforated; on this a layer of gravel, then alternate layers of

charcoal and white, clean sand, and top layer of excelsior, with

perforated cover ten inches from the top, and a discharge-pipe or

over-flow four inches from the top.

A cross-bar of wood, four inches square, is held across the head

of the barrel, through the centre of which a common wooden headed screw

held the filter in solid mass.

A discharge-cock in the bottom of the barrel, when opened,

carries off the sediment, and the closing of the feed-pipe allows the

filter to clear itself.

James W.

Tufts further mentioned “The cost, if I recollect, was about $3.00,

and…the result…was a perfectly clear liquid, a one-pound bottle of which

has been hanging by a string in a sunny window for over six weeks and no

sign of sediment or precipitation.”

The 1889

W. H. Hutchinson & Son Manufacturers and Dealers in Bottlers Supplies

catalog suggested a similar approach, plus additional thoughts on filter

maintenance:

TO MAKE A FILTER.

Take a large tub or barrel; fix into it, about 10

inches from the bottom, a false bottom of 1-inch boards, pierced with

1/8 inch holes. Cover this

false bottom with coarse gravel, then place over this a piece of

burlaps, then put on 4 inches of coarse ground charcoal, then 4 inches

of good sharp sand, then another layer of gravel, on top of this another

piece of burlaps, then another false bottom, filled with holes; fasten

this bottom down firmly.

Keep the filter well filled with water, and draw from the bottom, about

5 inches above the lower hoop.

Cork around the edge of the false bottoms with cotton batting, to

prevent the water running down between the staves and bottoms.

This filter should be cleaned two or three times a year, and new

sand and charcoal used at least once a year.

The water from this filter for the first few hours will run

muddy, but the second day will run clear.

HutchBook.com

HutchBook.com