Joseph Byrne Bottle Stopper

Joseph Byrne’s patent application was filed April

5, 1884 and specified:

I, Joseph Byrne…residing in

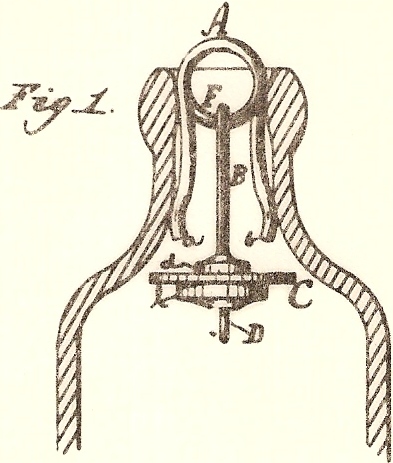

Figure 1 is a vertical section of the neck of a bottle

with my improved stopper therein unclosed.

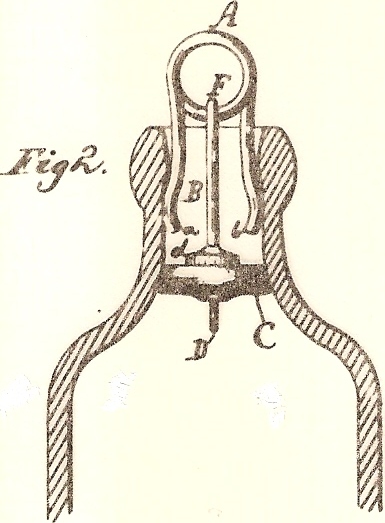

Fig. 2 is a vertical section with stopper therein closed.

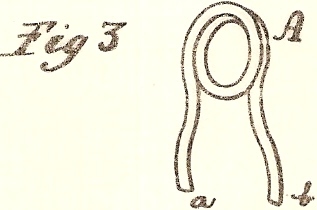

Fig. 3 is a detail of spring.

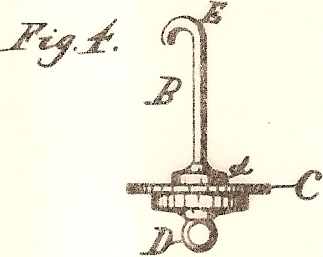

Fig. 4 is a detail of stopper and hook…

A is the spring,

made of any suitable numbered wire, having a single turn at upper end

and open at lower end, terminating in the two ends

a b.

B is a stem, having at

its upper end the hook E, and

at its lower end the washers d

and l, and between them the

rubber C, and at its extreme

lower end the ring D.

The lower washer, l, is

larger than the upper washer, d.

The hook e engages with

the ring F of the spring

A.

When in position for use, the spring

A is raised, as shown in Fig.

2. This causes the rubber

C to fold over against the

lower washer, l, and as it is

pressed against the interior of the neck of the bottle it forms a

perfect joint, as shown in Fig. 2.

This arises from the fact that the fold of the rubber over the

washer l makes it too large to pass through the neck.

When desired to pour out the contents of the bottle,

the spring A is pressed down, as shown in Fig. 1.

This releases the stopper below and allows the contents to be

poured out. The ring

F is made larger than the neck

of the bottle, so that it will not pass down through the neck into the

bottle. The stem

B being suspended from the

lower portion of the ring F, it always brings directly in the center of the neck, which

insures the stopper working evenly and squarely against the lower

portion of the neck, thus making a perfect seal or joint.

To remove the stopper, the spring

A is pushed slightly down,

just enough to free the hook from the ring, when with a piece of wire or

any convenient tool the hook is moved slightly to one side, just enough

to escape the ring, when the ring is removed from the bottle and the

stem drops down into the bottle.

The stem is then reversed by shaking the bottle, when a hooked

wire is inserted and engaged with ring

D, and the stopper is removed

from the bottle. In this act

the rubber C folds over the

upper or smaller washer, d,

which is sufficiently small to allow the stopper to pass out of the

neck.

I am aware that what might be called a “staple-spring”

has been used in bottle-stoppers, with the stopper hung or attached to

one or both ends of the lower extremities of the spring.

The hook E is open, as

shown in fig. 4, so it can be released at pleasure from ring

F when desired to remove the

stopper.

Comments:

This patent was included in this review because of the

descriptions detailing exactly how the stopper functioned.

Although Byrne described his stopper as “simple,” the stopper

removal process reads somewhat like a solution to a magic puzzle.

There is no evidence Byrne achieved any marketing success with

his closure.

HutchBook.com

HutchBook.com