Joseph Conner Bottle Stopper

Joseph Conner’s patent

application was filed March 13, 1886, and assigned to The Firm of John

Matthews. This patent

specified:

I, Joseph Conner, of…

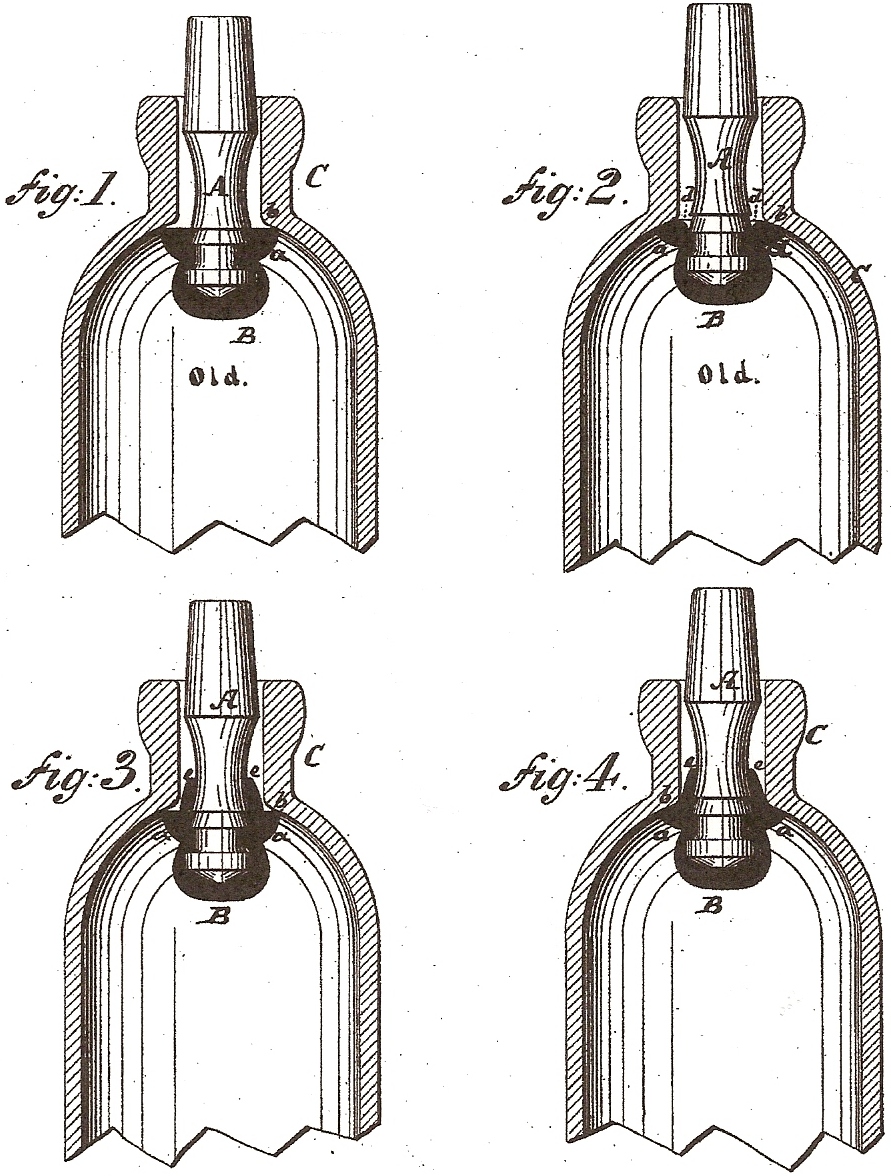

Figure 1 and 2 represent sectional side views of

bottle-stoppers of well-known construction, to which my invention is

intended to be applied.

Figs. 3 and 4 represent similar views of my improved stoppers.

The object of this invention is to provide certain

internal bottle-stoppers…which are intended to close upwardly with an

elastic peripheral flange against the seat in the throat of the bottle –

with a packing which shall at all times hug the stem of the stopper.

The old kind of stoppers, which I seek to improve, is

represented in Figs. 1 and 2 of the drawings, and consists of a rigid

stem, A, and a rubber or

other flexible packing, B,

which packing is slipped upon the lower end of the stem, so as to

tightly embrace and surround the same.

The packing B has an

outwardly-projecting flexible flange,

a, which seats against the

throat b of the bottle

C.

The difficulty with this kind of stopper is that when pressure is

applied internally against the stopper the flange

a will be distended or

crowded outward, as is clearly shown in Fig. 2, so as to partly draw the

upper portion of the packing away from the stem

A and produce an annular

cavity, d, around said stem.

This cavity will remain open to the reception of dust, insects,

and other impurities during the entire period of time the bottle is

charged with gaseous liquid, and when afterward the bottle is emptied

the packing B will again

close on the stem and grasp and retain the impurities which settle in

said cavity or groove d.

As these stoppers, when the bottle is being opened,

are forced into the liquid contents thereof, the aforesaid impurities

will become in part absorbed by the liquid, tainting the same.

This is one of the principal difficulties connected with the use

of ordinary bottle-stoppers.

They serve to taint the liquid by the above-mentioned impurities

and at all times to retain sufficient of the impurities to be

objectionable in continual use.

The stoppers, being within the bottle, cannot conveniently be

cleaned, especially if the impurities settle, as has been stated, in a

cavity, which becomes subsequently closed whenever the bottle is opened.

My invention consists in providing a packing of the

kind stated, and which surrounds the lower part of the stem and carries

the flange a, with an upward

projection, e, on the packing

directly above the seat or flange portion

a, so that said

upwardly-projecting tubular portion

e of the packing will at all

times tightly hug the stem A.

When pressure is applied to the stopper from within and the

seat or flange portion a

distended, as in Fig. 4, the tubular projection

e will thereby be drawn down

on the stem, still tightly hugging the same, all as shown in Fig. 4.

By this means the objectionable open groove or cavity heretofore

referred to is avoided, and all danger of contaminating the liquid with

impurities that settle in the folds of the stopper obviated.

Comments:

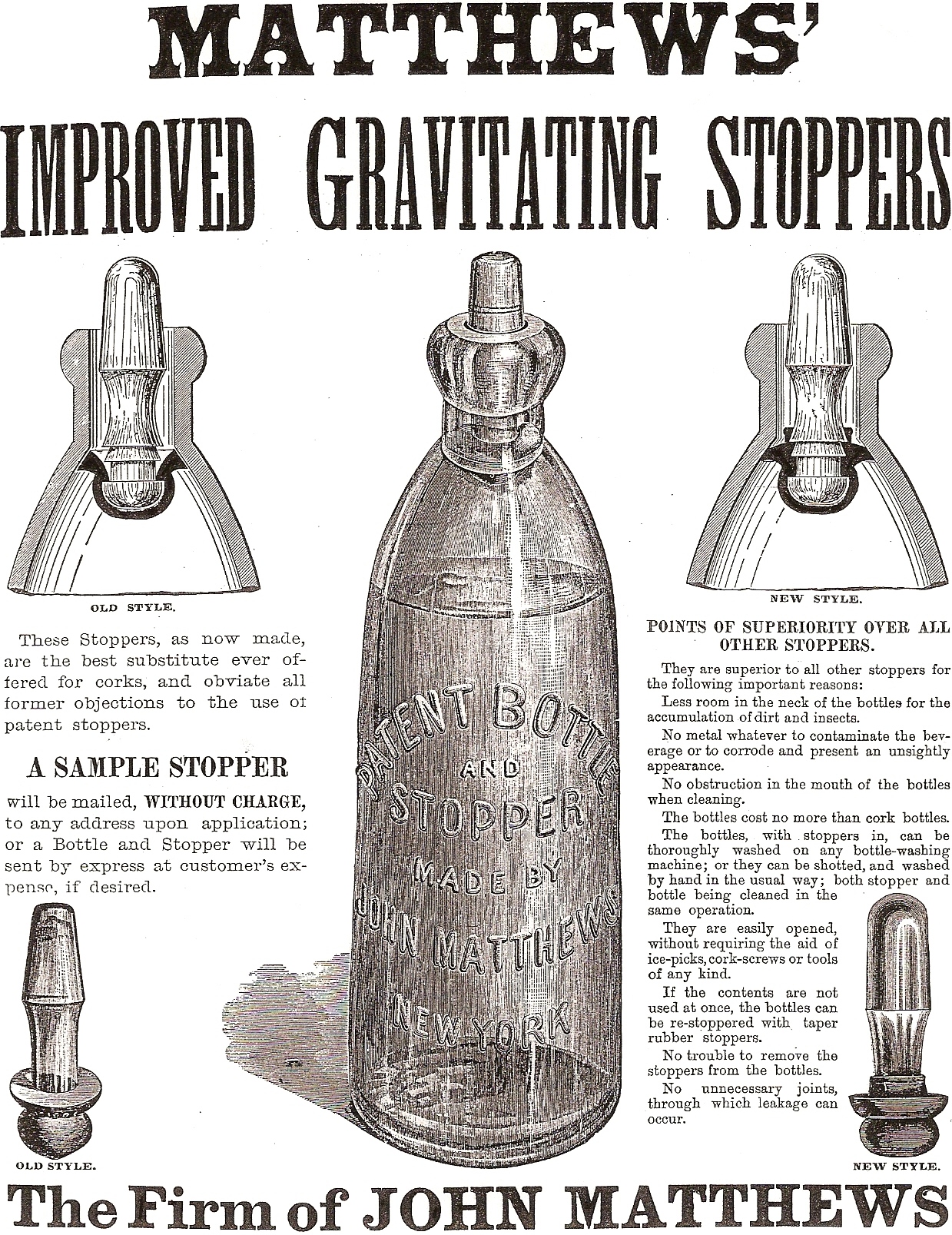

This patent was included in this review to highlight

the industry’s continuing struggle to prevent the contamination of

bottle contents. See

Matthews Patents No. 67,781 and 137,941 for additional comments about

Matthews Gravitating Stopper bottles,

Hutchinson Bottle Directory

cataloguing guidelines, and previous design improvements.

Soon after John Conner’s patent was granted, The Firm of John Matthews

began to advertise these latest improvements.

The following advertisement ran in the March 1, 1887 issue of

National Bottlers’ Gazette

(a special THANK YOU to David Graci, author of

Soda and Beer BOTTLE

CLOSURES 1850 – 1910 for providing this great illustration).

Although this advertisement mentioned the improved stoppers were

“the best substitute ever offered for corks, and obviate all former

objections to the use of patent stoppers,” the “POINTS OF SUPERIORITY

OVER ALL OTHERS STOPPERS” were clearly aimed at slowing down the rapidly

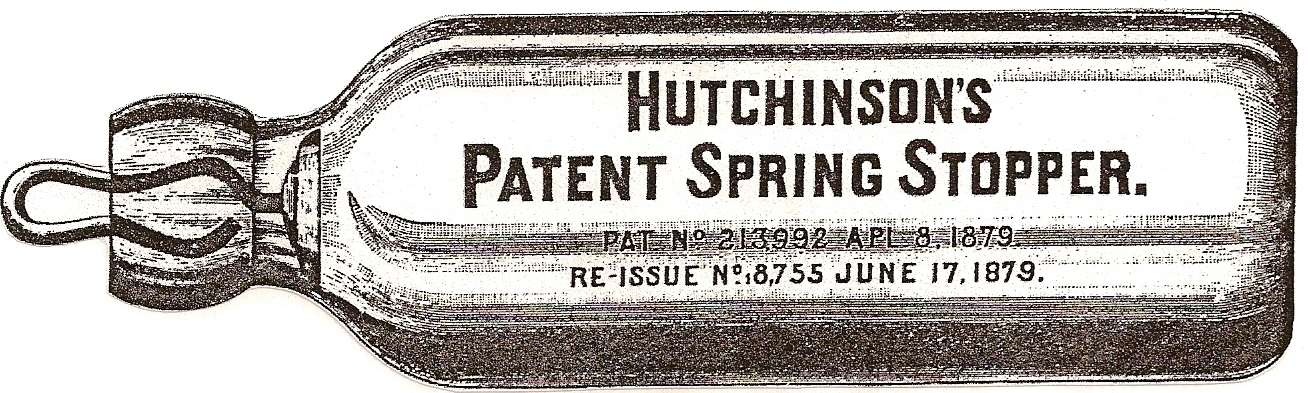

increasing conversion to the use of

HutchBook.com

HutchBook.com