William Stewart Bottle Stopper

William Stewart’s

1886 patent application was filed October 19, 1885 and specified:

I, William Stewart…of…Brooklyn…

This invention relates to a new and improved

self-acting internal stopper for bottles containing or intended to

contain soda-water or other liquid charges with gases; and the objects

are to produce a stopper which can be used in any bottle, which will be

buoyant enough to float on the liquid and light enough to be lifted by

the internal pressure to its seat in the neck of the bottle without

requiring a lifting device or the bottle to be tilted or inverted, and

which will not necessitate the use of any special kind of machine for

filling or cleaning the bottle.

Heretofore internal stoppers, usually of a spherical

shape, have been employed, and such stoppers may be divided into two

classes – viz., first, gravitating stoppers, or stoppers of greater

specific gravity than the liquid, and, second, floating stoppers, or

stoppers of less specific gravity than the liquid.

Stoppers of the first class have heretofore consisted of a solid

glass ball or a weighted hollow ball, and in some cases of a flat disk

of pearl, ivory, or glass, and those of the second class of hollow balls

composed of glass, porcelain, or sheet metal, and in some cases of a

flat or nearly flat disk of several layers of cork or pearl or cork and

india-rubber, or a ball composed of elastic material has been employed;

but all such stoppers were objectionable in that they required special

manipulation in filling and cleaning them, and, further, because to

bring the stopper to its seat in the neck of the bottle, after the

latter had been filled, it was necessary to use a lifting device or to

tilt the bottle, so that the stopper would drop into the neck, thus

causing a waste of liquid and gas.

By my invention I seek to produce a stopper which will

obviate all these objections; and to this end my invention consists in a

self-acting internal stopper, preferably composed of hard non-elastic

material – such as vulcanized rubber – and which is buoyant enough to

float on the liquid and light enough to be impelled to and seated

against the packing-ring automatically by the gaseous pressure within

the bottle without extraneous assistance or manipulation…

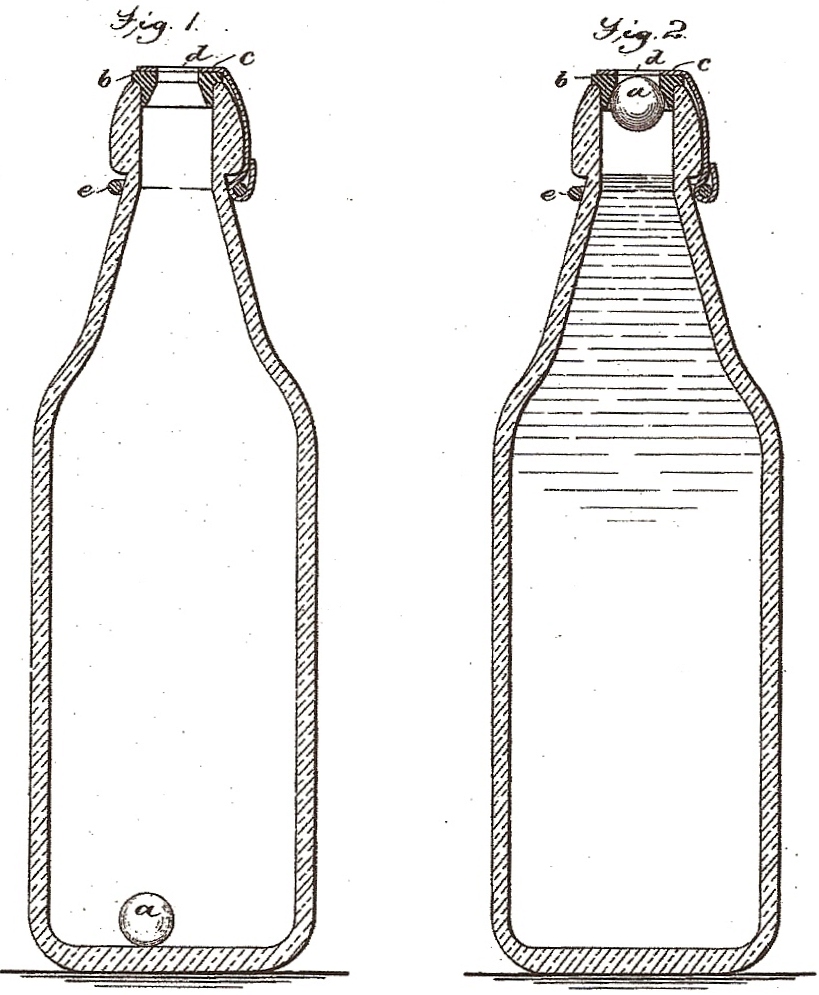

Figure 1 is a sectional view of an empty bottle

supplied with my improved stopper.

Fig. 2 is a similar view of a bottle filled with the liquid.

Fig. 3 is a section of my improved stopper.

The stopper, a is composed of two semi-spherical

shells, united to form a hollow ball.

I propose to make these stoppers of hard vulcanized rubber, as

this is the only material I have been able to find from which it is

possible to make a practically useful stopper of the requisite buoyancy

and lightness. I have found

by careful practical experiments that is not possible to make a

self-acting stopper from glass, porcelain, sheet metal, or elastic

material, and that while cork is light enough for the purpose it is very

objectionable, because it will rot, and thus render the stopper useless

in a short time.

A stopper of elastic material, as heretofore made, is

not light enough to be self-acting to close the bottle when the bottle

is in the usual upright position during the filling process, and is too

buoyant to roll into the neck to close the mouth of the bottle when it

is inverted…(and)…unless they are of greater diameter than the inside

diameter of the neck of the bottle they are liable to be blown out of

the bottle by the internal pressure…

Stoppers composed of glass, porcelain, or sheet metal,

besides not being self-acting, are objectionable, because of the

liability of breakage of the bottle or the stopper during the washing,

filling, or emptying of the bottle, and, further, because they require a

bottle of special construction to prevent the stopper from rolling back

to its seat in the neck when the liquid is being poured out…

A floating stopper composed of a flat or nearly flat

disk is objectionable, in that it is difficult to get such a stopper

properly seated, as it requires a special construction of the neck of

the bottle to make a gas-tight joint.

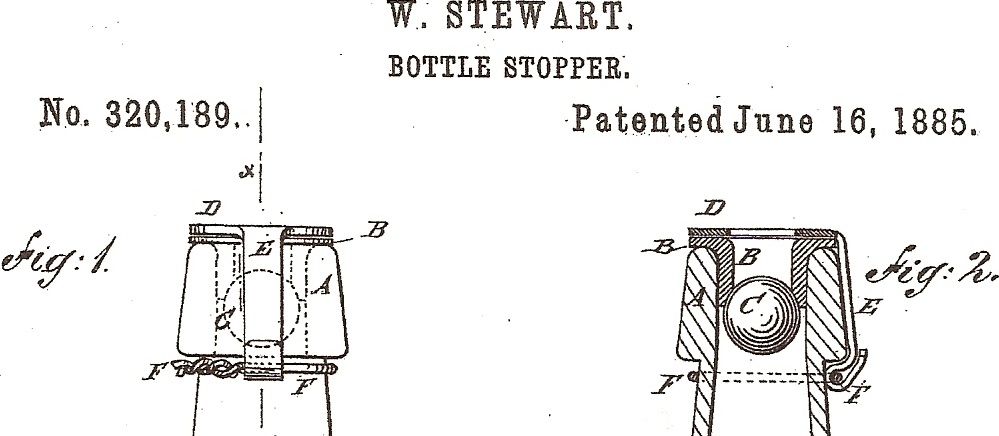

In Figs. 1 and 2 of the drawings I have shown my

improved stopper in connection with a bottle supplied with a cap of the

construction described and claimed in…Letters Patent No. 320,189,

granted to me June 16, 1885…

In these (1886) figures of the drawings,

a designates the stopper,

b a soft packing, and

c a metal cap.

The packing is ring shaped, and is laid over the edge of the

mouth of the bottle, and held there by the cap, which has a central

aperture, d.

This cap is provided with arms which are bent around a fastening

wire, e, which encircles the bottle neck.

The bottle itself is of ordinary construction, and the stopper of

less diameter than the inside diameter of the neck.

When the bottle is filled, the stopper

a rises to the surface of the

liquid, and is then lifted by the internal pressure to its seat against

the packing, thus closing the bottle.

When the liquid is to be poured out, the stopper is pushed from

its seat by means of a rod or other suitable implement, and rises

through the liquid to the highest part of the bottle, when the latter is

tilted or inverted to discharge its contents.

My improved stopper, with a

ring-shaped packing and aperture cap, can be applied to any bottle, and

the bottle can be filled by any ordinary bottling-machine in the market,

thus enabling a bottler of soda-water or other liquids charged with gas

to utilize bottles which are now practically useless, resulting in a

saving to the bottling trade of many thousand dollars every year.

Comments:

William Stewart’s patent specifications outline many

of the challenges bottlers and customers faced, and in combination with

the illustrations provide a fairly easy-to-understand description of his

stopper’s design and how it functioned.

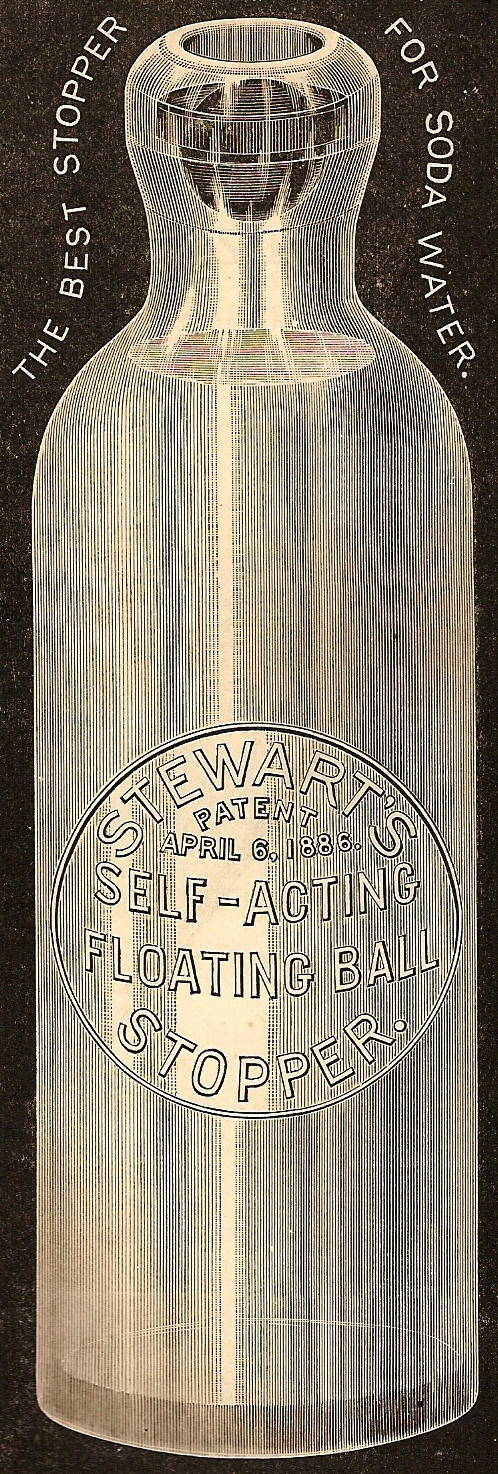

Once the patent was approved, a Stewart Bottle Stopper Company

advertisement in an 1886 issue of the

National Bottlers’ Gazette

proclaimed:

THE STEWART PATENT SELF-ACTING SODA WATER STOPPER IT

BEATS THEM ALL.

The Self-Acting Floating Ball Stopper is a light,

hollow ball, a mere shell, but strong enough to bear the weight of a man

and hard enough to withstand the action of acids.

It is, therefore, impervious and will not contaminate the

beverage…

DIRECTIONS TO FILL – To fill these bottles you simply

place it right end up, like you would fill a bottle with a cork, and

place a cork in the cylinder, and instead of driving it you leave it

remain, to prevent the flow of water up through the cylinder.

That is all there is to it.

It is just as easy and as simple as rolling off a log.

See the point? When

you desire to open a bottle, when it is freshly bottled, with the foam

filling the neck, use an opener to force the ball to the liquid.

After the foam has subsided, you can drop the ball to the liquid

by one quick motion of the forefinger.

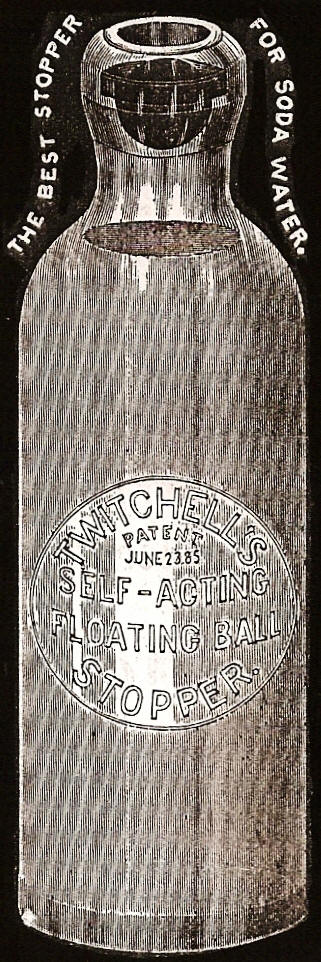

Bottles utilizing Stewart’s 1885 patent stopper are

known, but we’ve yet to see an example matching the Self-Acting Floating

Ball Stopper bottle as illustrated and described in his 1886 patent.

Historical research has yet to fill a major gap in this story, as

there certainly appears to have been an as-yet-to-be-determined business

relationship between William Stewart, Selden Twitchell (of the Twitchell

Bottle Stopper Company of Philadelphia, Pennsylvania), and William

Roorbach.

In 1885 the Twitchell Bottle Stopper Company was

advertising “Twitchell’s Self-Acting Floating Ball Stopper.”

Less than a year later, an identical closure was being marketed

by the Stewart Bottle Stopper Company of

The floating-ball stoppers promoted by Twitchell,

Stewart, and Roorbach achieved limited marketing success with bottlers

across

TWITCHELL’S Patent Floating

Ball STOPPERS

IS THE BEST IN EVERY WAY FOR

BOTTLING CARBONATED BEVERAGES.

1 – It can be

filled and

stoppered with any

Bottling Machine, hence no expense in adopting it.

2 – It is filled and stoppered

quicker than

cork or any other patent stopper.

3 – It has

no metal about it to contaminate beverages with

metal poisons.

4 – It has

no soft rubber to come in contact with or to contaminate

the beverages with obnoxious flavors or odors as with all other patented

stoppers.

5 – All

parts of this stoppered bottle can be washed

quickly and

thoroughly

with brush, shot or any bottle-washing machine.

6 – It has

no protruding stopper to be knocked down by placing

filled cases on top of each other, therefore much more safe.

7 – It is more quickly opened than any other stoppered

bottle, and as the ball quickly leaves the mouth when opened, there

being no obstruction in the mouth of the bottle, the beverage flows out

quickly, without any agitation at the expense and loss of carbonic gas.

8 – This bottle has

no crevices or

irregularities about it to prevent its

thorough

cleansing in every part.

9 – No flies or dirt can get into the bottle after

being emptied, to rot and breed maggots, if, after being washed and

drained, it be placed in box or case, mouth downward, as the ball drops

to the mouth and prevents flies or dirt from getting into it.

10 – It cannot be used for

spirituous liquors

of any kind, nor for root

beer or

ketchup.

11 – When properly filled about to the shoulder, even

though frozen solid, the bottle will not break if thawed out in cool

water.

12 – The bottles for our Patent Stopper can be made in

private moulds that are used for making bottles for cork or any of the

metal spring stoppers, by enlarging the part of the moulds that forms

the neck of the bottles.

13 – Our Patent Floating Stopper is of such shape and

material as to withstand all wear without being broken; hence there are

no repairs or replacing of parts at considerable expense and labor, as

this is with all

other patent stoppers for same purposes.

14 – Our Patent Floating Stopper is so little affected

by wear that it will outlast one hundred of the metal spring style of

stoppers.

We supply Special “Finishing Tools” so any Glass

Factory can make Perfect Bottles

Price of Twitchell’s Floating Ball Stoppers, Fittings

Complete, $2.25 per Gross.

Our Hard Rubber Floating Ball Stopper, $1.25 per gross.

Our Patent Rubber Bushing, $1 per gross.

The Twitchell Bottle Stopper

Co.,

HutchBook.com

HutchBook.com