Frederic R. H. Thomas Internal Ball Valve Bottle

Frederic

R. H. Thomas’ patent application was filed March 18, 1892 and specified:

I, Frederic R. H. Thomas…of Catskill…

My improvement relates to bottles having, interiorly,

ball-valves closing against seats in the neck of the bottle by the

outward pressure of the gas contained in the bottled liquid – such as

the carbonic-acid gas of ordinary “soda-water,” so called, ginger-ale,

&c. In relation to the

ball-valves used such bottles may be divided in two classes – those

having heavy or sinking valves and those having light or floating

valves. In order to prevent

the valve of the former class from rolling to its seat and shutting off

the flow when pouring out the liquid, the bottles are provided in the

neck or in the side near to the bottom with pockets formed in the

molding, to receive and retain the ball-valve while emptying.

Beside the inconvenience of manipulating the bottle so that the

ball will reach and lodge into one of the said pockets, the pockets

gather dirt and gum, which not only causes the ball to stick there when

not wanted, but makes cleaning difficult and tedious.

Moreover, the location of the valve-seat too far below the mouth

of the bottle makes the valve inconvenient of access in opening and the

long, narrow cylindrical, or too slightly conical neck makes it

necessary to use special means, beside the fingers, to push the ball so

far down as to prevent its being pushed back toward the seat by the

outward rush of the liquid impelled by the gas-pressure.

In bottles having floating ball-valves and improved by

having no pockets another objection exists – namely, that the very light

ball jumps back to its seat time and again when opening, thereby causing

the gas-charged liquid to spatter over the person who opens it, and

sometimes it lodges on the foam and is slow to recede from the neck even

though the bottle be inverted.

Again at times when after emptying a small portion of the liquid

remains, the sweet or gummy ingredients therein will cause the light

ball to adhere to the inner surface of the bottle so hard as to impede

considerably the process of washing.

The usual length of the necks of bottles of both

classes makes them all very liable to be broken.

In those having sinking ball-valves and pockets at the bottom the

bottle must be held upright until the ball has lodged in the said

resting-place. In the

meantime the liquid foams out of the bottle without getting into the

drinking-glass and is wasted.

If the bottle is inclined before the ball has thus lodged, the

ball immediately rolls into the neck and stops the flow of the liquid.

The valve-seat of the ring in the bottle-neck, as heretofore

constructed, has unnecessarily large surface, requiring proportionately

too high pressure to tighten the valve and requiring larger depression

to remove it from its seat in opening.

In order to obviate the aforesaid objections, my

improvement comprises a bottle whose breast forms a square shoulder at

the junction of the body and neck, of a depth not less than the

semi-diameter of the ball, to form a retaining-ledge, a very short

downwardly abruptly flaring or widening neck, narrowest at its upper

end, where it meets the square cut groove, and of a length substantially

the same as its width at the said narrowest point, as shown in the

drawings, and a valve-ring seated in a groove so as to project therefrom,

presenting a sharp edge for contact with the valve and located so near

to the mouth of the bottle as to bring the ball within, say, one-fourth

of one inch below the same, and thus easily accessible to be depressed

by the thumb to drop from its seat when desired to empty the bottle…

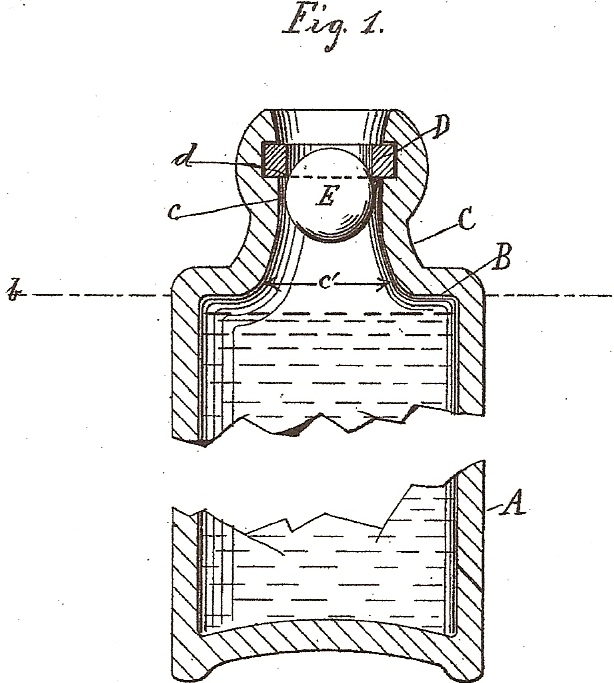

Figure 1 represents a bottle embodying my improvements

and in upright position with valve closed.

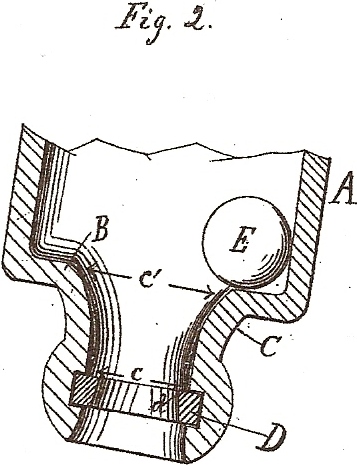

Fig. 2 shows the same inverted and with valve open as when just

emptied…

In opening the valve drops instantly, there being

plenty of space between the valve and the inner surface of the neck for

the liquid to pass without carrying the valve with it, and the contents

are never spattered. The

extra shortness of the neck saves breakage and the bottle is much easier

cleaned than bottles heretofore used for gaseous beverages…After filling

the bottle the ball will take its seat upon the ring

D quickly, thereby saving

largely in gas, gas-water, flavor, &c., otherwise spilled and wasted.

The valve-seat is formed by a rubber ring

D, inserted in a groove in the

bottle-neck, as usual, but the seat proper is not beveled, the hole in

the ring being cylindrical, as in Fig. 1, or tapering inward, as in Fig.

2, in either case leaving a sharp corner or annular edge d to receive

and seat the ball-valve. The

ball is of the heavy or sinking kind.

Comments:

This interesting patent is included in this overview

because Thomas’ specifications detail many of the challenges bottlers

and customers experienced with both heavy and light ball-stoppered

bottles. Although Thomas’

bottles are sometimes confused with

HutchBook.com

HutchBook.com