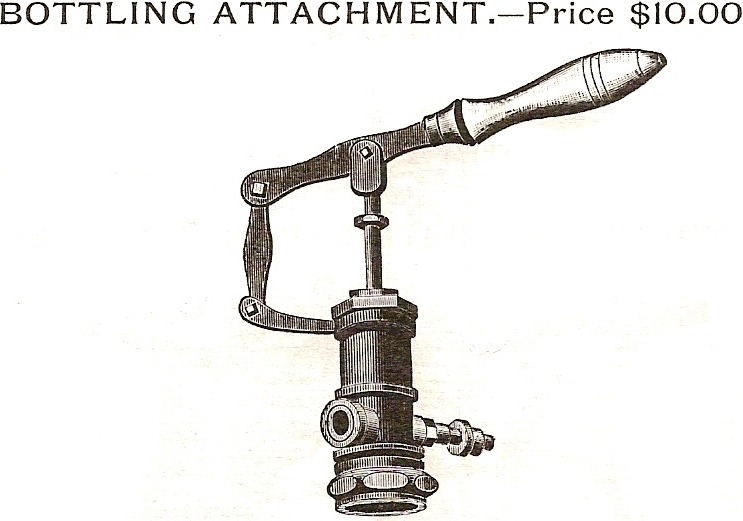

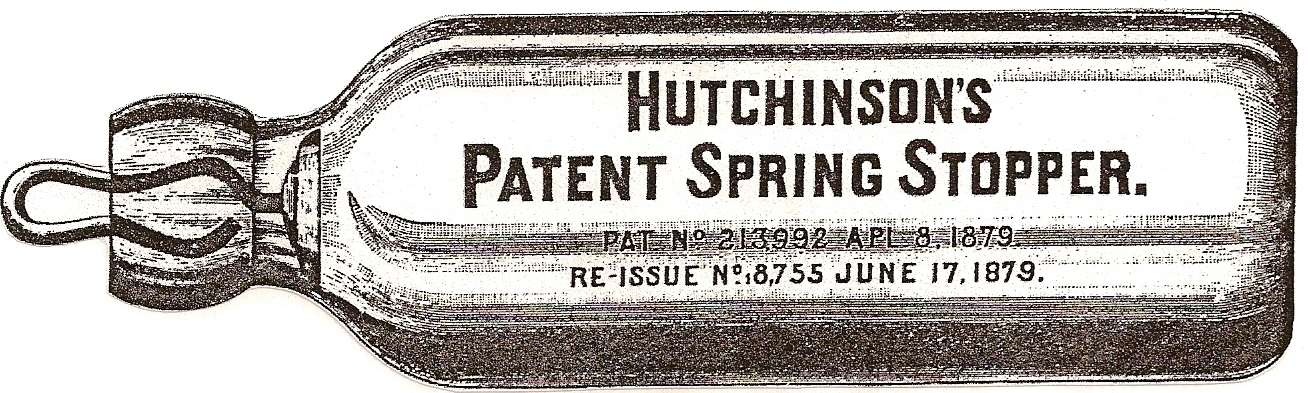

Hutchinson Filling Head

Once the bottle was full, the

arm was pushed back to shut off the flow of carbonated water and draw

more syrup for the next bottle to be filled.

The bottler then pulled up on the handle on the

In

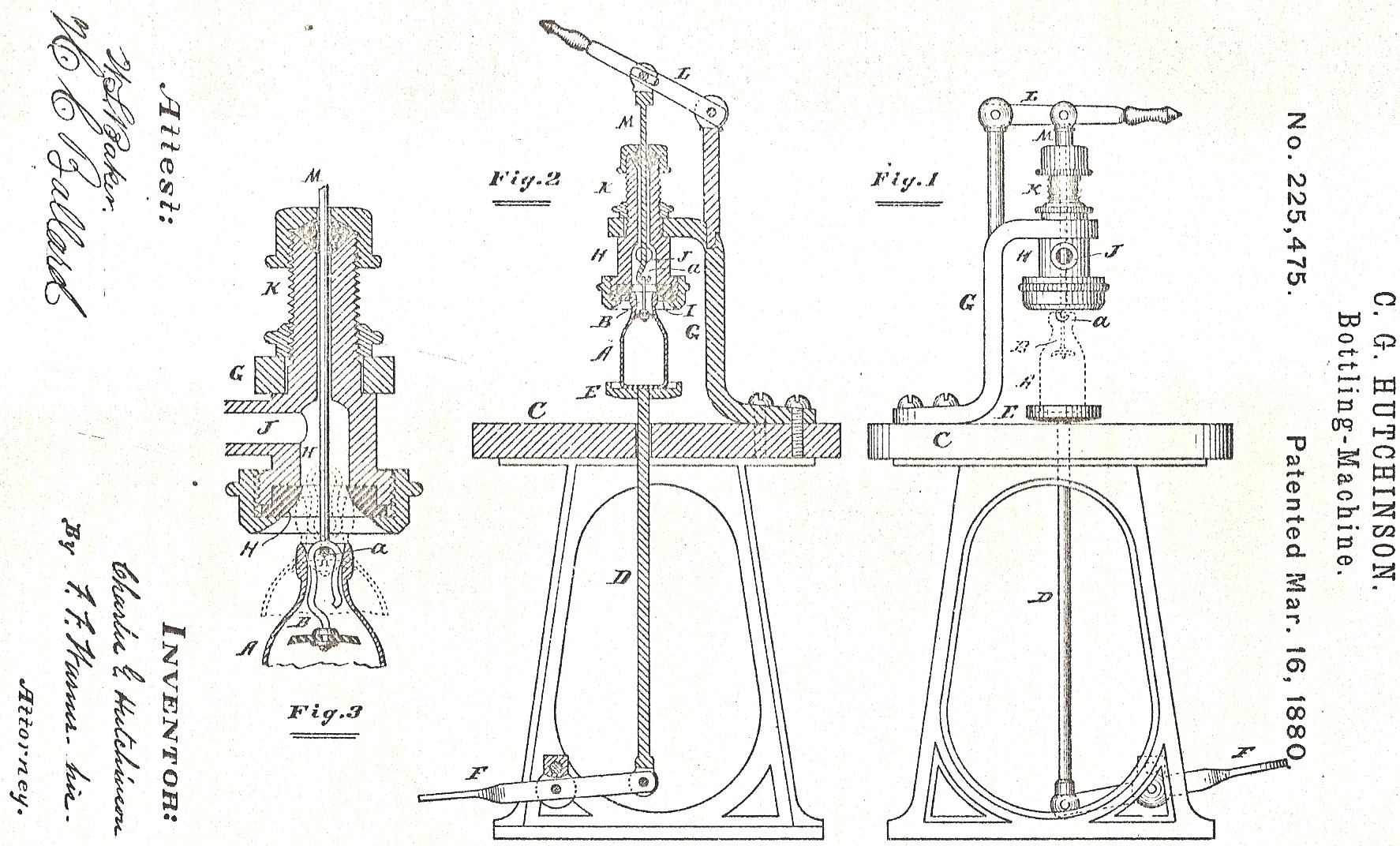

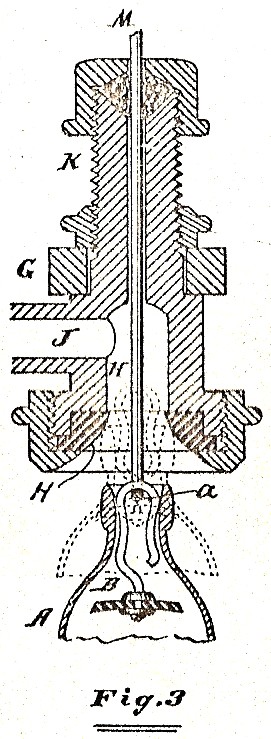

Charles G. Hutchinson’s own words, his Patent No. 225,475 granted March

16, 1880 described the filling process as:

The bottle to be filled is placed on the disk or

bottle-support...the stopper being first depressed or pushed down to its

open position, where it will be suspended approximately in a central

position with relation to the neck of the bottle.

The hook is then inserted into the loop of the stem of the

stopper…usually the act of placing the bottle on its support and of

hooking the stopper-stem to the plunger may be performed at about the

same time. I then depress

the treadle, by which means the bottle will be held up firmly against

the cushion. The liquor may

now be allowed to enter through the pipe, and as soon as the bottle is

filled the lever should be raised enough to draw the stopper to its

closed position…After it is closed the treadle and the hand-lever should

be released, when the bottle will descend to a position which will admit

of it being easily removed; but before releasing the bottle the flow

through the pipe should be shut off, it being understood that the cock

therein was opened after the bottle was raised to its cushion.

The most common use to which this machine will be applied,

probably, will be the bottling of aerated liquors, and when so used the

cylinder should be provided with an air-vent to prevent the gas from

interfering with the filling of the bottle.

Here are the accompanying Patent No. 225,475 drawings, and a close-up/enlarged look at Figure 3:

James W. Tufts’ 1888 book,

The Manufacture and

Bottling of Carbonated Beverages, included the identical “

Directions for Using.

To adjust the Bottling Attachments for Stoppers into

Corking-Tables:

Third.

– Put in the stopper attachment and have the bracket that holds the

lever for pulling up stoppers, between the cross bar holding

filling-head and back nut that holds the filling-head in place.

This gives the lever ample play so that the stopper can be pulled

to its closed position.

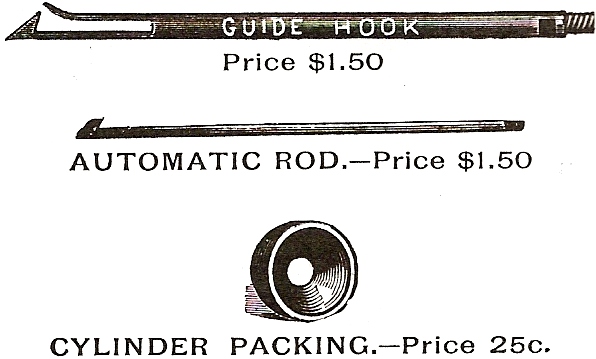

To fill the Bottles with a Plain Hook: - Place the

bottle under the cylinder; catch the hook in the stopper, then lower the

cylinder to the bottle; open the syrup and water-gauge; when filled,

close the syrup-gauge, draw up the stopper, and raise the cylinder.

The bottle is filled.

To Bottle with Automatic Rod: - Place the bottle under

the cylinder; lower the cylinder to the bottle; open syrup and

water-gauge; when filled, shut off the syrup-gauge, lower the rod, and

pull up and the bottle is filled.

To Bottle with Guide Hook: - Put the bottle under the

cylinder; lower the cylinder upon the bottle; open syrup and

water-gauge; when filled, shut off syrup-gauge; lower hook, and pull it

up again, and bottle is filled and stopper closed.

Always turn guide towards the operator putting in and taking out

bottles.

Price of Hutchinson’s attachment, . . . . . . . . . .

. . . . . $10.00.

These guide hook, automatic rod (also referred to as a

“plain hook”), and cylinder packing illustrations appeared in the 1889

W. H. Hutchinson & Son

Manufacturers and Dealers in Bottlers Supplies catalog:

After

filling, another bottle was placed on the table and the process was

repeated. Although the

process sounds quite slow, experienced bottlers filled bottles very

quickly. Most had one

assistant placing empty bottles on the table, and another one removing

bottles after filling, leaving the bottler to simply operate the syrup

gauge, filling head, and treadle.

These

HELP FOR SYRUP PUMP.

By John J. Burdell, Key West

Bottling Works,

To greatly aid the jam nut (which is at connection

of syrup pump and Hutchinson attachment) to do its work, fasten the

back end of the syrup pump cylinder, either from the table, or by a

wire from above, to keep it from dropping down.

I have mine hanging from a wire from above and it has been a

great help to me.

FOR THE

By Chesterman Company,

Take an elastic band, tie strings at each end,

attach one end to hook handle, other to ceiling or other place

directly above table.

This keeps the hook up out of the way, and saves time and stoppers.

IN BOTTLING WITH

By A. Kantrowitz & Son,

I have found that by attaching a spring to the

handle and fastening same to the ceiling directly above the handle

that about thirty seconds is gained in speed.

That spring always keeps the hook high and so does not

interfere with the charged water; thereby it fills fast, leaks very

little, and the only motion necessary to stopper bottler is to pull

down the spring, forcing the stopper up itself.

HutchBook.com

HutchBook.com